Optimizing Chemical Dosage for Effective Chilled Water System Performance

Chemical Dosing in Chilled Water Systems

Chemical dosing in chilled water systems is an essential practice in modern HVAC (Heating, Ventilation, and Air Conditioning) operations. These systems are crucial for maintaining comfortable indoor environments in commercial and industrial buildings. Effective chemical dosing ensures optimal system performance, longevity, and efficiency, all while preventing potential issues related to corrosion, scaling, and biofouling.

In a chilled water system, water is circulated to transfer heat from indoor spaces to a cooling tower or heat exchanger. Over time, various contaminants can accumulate in the water, including minerals, biological organisms, and sediment. If left untreated, these impurities can lead to scale buildup on heat exchange surfaces, reduced thermal efficiency, and concomitant increases in energy consumption. Furthermore, the presence of microorganisms can cause biofilm formation, resulting in poor water quality and potentially harmful bacteria proliferation.

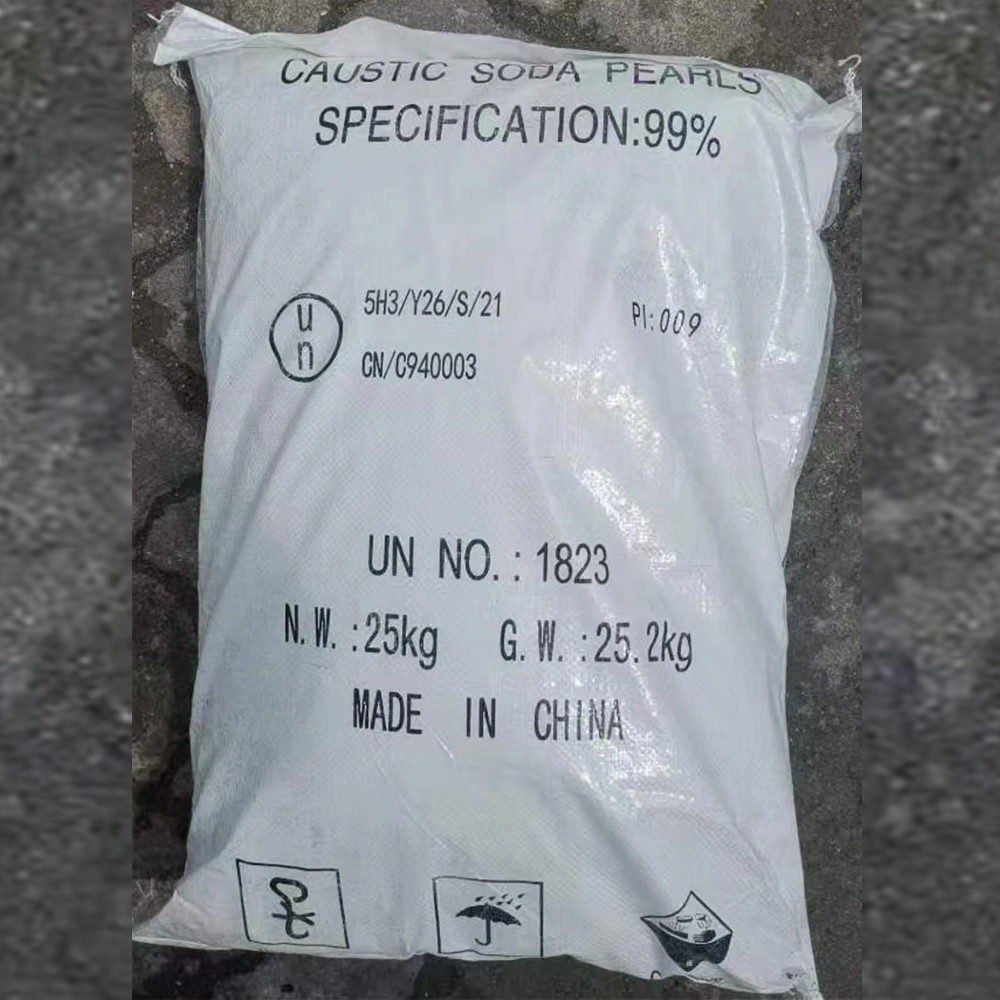

To counter these risks, chemical dosing is implemented. This process involves the careful introduction of specific chemicals into the system at calculated intervals and concentrations. Common chemical treatments include biocides, corrosion inhibitors, scale inhibitors, and pH adjusters. Each chemical plays a unique role in maintaining the integrity and efficiency of the chilled water system.

chemical dosing in chilled water system

Biocides, for instance, are used to control the growth of algae, bacteria, and other microorganisms in the water. By preventing microbial growth, these chemicals help to maintain water quality and minimize health risks associated with Legionella and other pathogens. Corrosion inhibitors, on the other hand, form a protective layer on metal surfaces, safeguarding them from rust and galvanic corrosion. This protective action extends the lifespan of system components, reducing maintenance costs and downtime.

Scale inhibitors work by interfering with the crystallization process of minerals, thereby preventing the formation of hard deposits on equipment. This is crucial for maintaining high thermal efficiency and reducing energy costs, as scaling can significantly decrease heat transfer performance. Additionally, pH adjusters are used to maintain optimal acidity levels in the water, further preventing corrosion and scaling.

Implementing a robust chemical dosing program requires careful monitoring and control. System operators must regularly test water quality parameters and adjust chemical dosages accordingly. Automated dosing systems are increasingly being employed to enhance precision and reduce the risk of human error, ensuring that water chemistry remains within optimal ranges.

In conclusion, chemical dosing in chilled water systems is vital for maintaining operational efficiency, prolonging equipment life, and ensuring safe and comfortable environments. By leveraging the right chemical treatments and employing thorough monitoring practices, building managers can optimize their chilled water systems, resulting in significant cost savings and enhanced performance.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025