Innovations in Chlorate Electrolysis for Sustainable Chemical Production and Energy Solutions

Chlorate Electrolysis An In-Depth Exploration

Chlorate electrolysis is a significant electrochemical process that plays a crucial role in both industrial applications and environmental management. This method primarily involves the electrolysis of salt solutions to produce sodium chlorate (NaClO₃), a compound with wide applications, particularly in the paper and pulp industry, as well as in various chemical manufacturing processes.

The Basics of Chlorate Electrolysis

Electrolysis itself is a technique that uses electric current to drive a non-spontaneous chemical reaction. In the context of chlorate electrolysis, an aqueous solution of sodium chloride (brine) is subjected to an electric current. The electrolysis process occurs in an electrolytic cell, where two electrodes are submerged in the brine solution. When an electric current passes through the cell, oxidation and reduction reactions occur at the anode and cathode, respectively.

At the anode, chloride ions (Cl⁻) are oxidized to chlorine gas (Cl₂), while at the cathode, water is reduced to produce hydrogen gas (H₂) and hydroxide ions (OH⁻). The overall process leads to the formation of sodium hydroxide (NaOH) and sodium chlorate. The balanced chemical equations for these reactions illustrate the complexities of the electrochemical process

- At the anode \[ 2Cl⁻ \rightarrow Cl₂ + 2e⁻ \]

- At the cathode \[ 2H₂O + 2e⁻ \rightarrow H₂ + 2OH⁻ \]

- Formation of sodium chlorate \[ NaOH + Cl₂ \rightarrow NaClO₃ + HCl \]

Applications of Sodium Chlorate

chlorate electrolysis

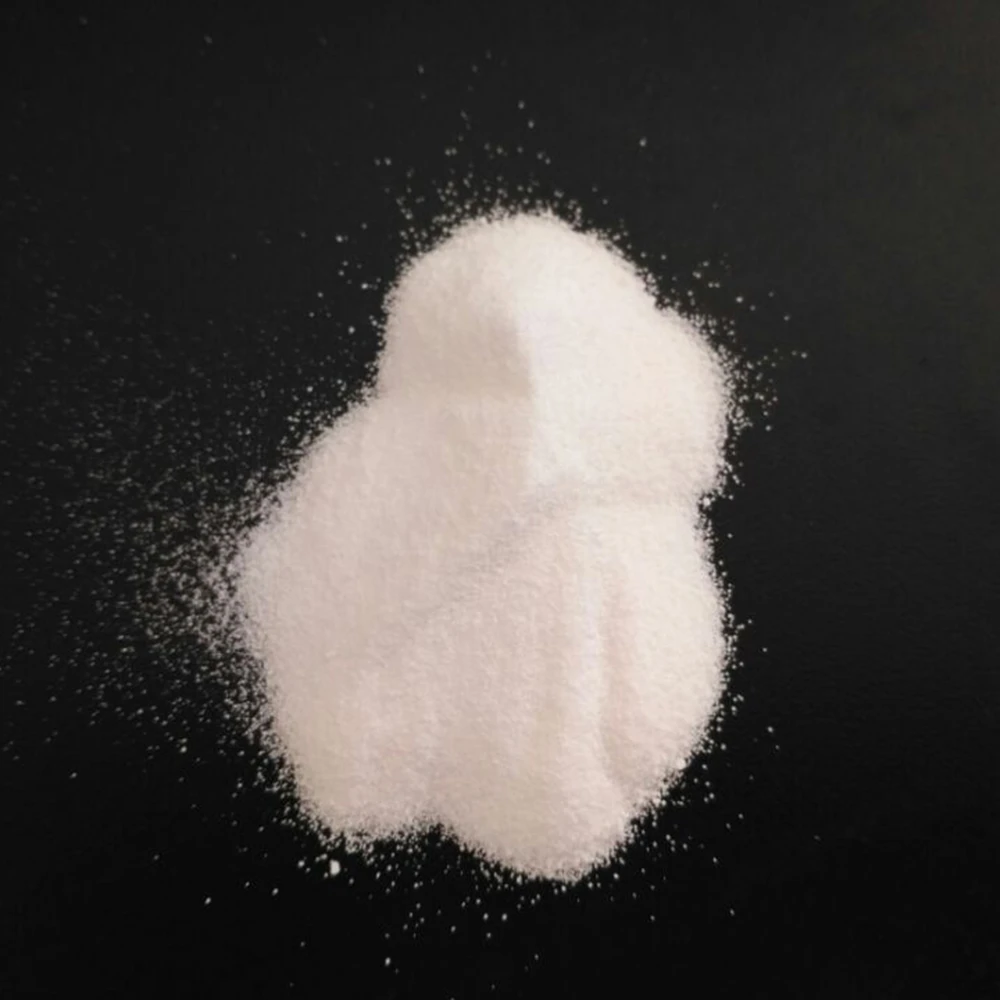

Sodium chlorate produced through electrolysis is predominantly used in the pulp and paper industry for bleaching wood pulp. It is favored for this application due to its effectiveness in removing lignin and other colored compounds from the cellulose, yielding a higher-quality product. Additionally, sodium chlorate functions as a herbicide, and its role in the synthesis of chlorine dioxide makes it fundamental in waste treatment processes.

Moreover, sodium chlorate serves as an oxidizing agent in various chemical reactions and can be found in processes related to the manufacturing of explosives, including chlorate-based pyrotechnics. Its versatility and efficacy make it a key compound in multiple sectors, driving advancements in production methods and sustainability initiatives.

Environmental Considerations

While the chlorate electrolysis process is essential for industrial applications, it is not without environmental implications. The generation of chlorine gas and its compounds can pose environmental risks, including potential toxicity to aquatic ecosystems if released inadvertently. Consequently, regulatory bodies impose strict guidelines on the management of waste and emissions from chlorate production facilities.

Efforts to minimize the environmental impact have spurred research into more sustainable practices, including the improvement of electrode materials and the optimization of the electrolysis process to increase efficiency. One promising area of research focuses on using alternative brine sources and renewable energy to power electrolysis, thereby reducing reliance on fossil fuels and decreasing operational costs.

Future Trends in Chlorate Electrolysis

The future of chlorate electrolysis looks promising with ongoing advancements in electrochemical technologies. The integration of nanotechnology, better electrode designs, and innovative process controls can significantly enhance the efficiency of sodium chlorate production. Researchers are also investigating the potential for co-production of valuable by-products, which could further justify the economic viability of chlorate electrolysis.

Moreover, the increasing global emphasis on sustainability and environmental impact reduction is likely to drive innovations in this field. Enhanced methods to capture and recycle chlorine gas, improved waste treatment protocols, and the exploration of alternative feedstocks are all areas that could redefine the landscape of chlorate production in the coming years.

In conclusion, chlorate electrolysis stands as a vital segment of modern chemistry and industrial processes. Balancing its industrial utility with environmental considerations continues to be a priority, shaping research and operational practices within the sector. As technologies evolve, so too will the capabilities and efficiencies associated with this essential electrochemical process, fostering a sustainable future for chlorate production and its applications.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025