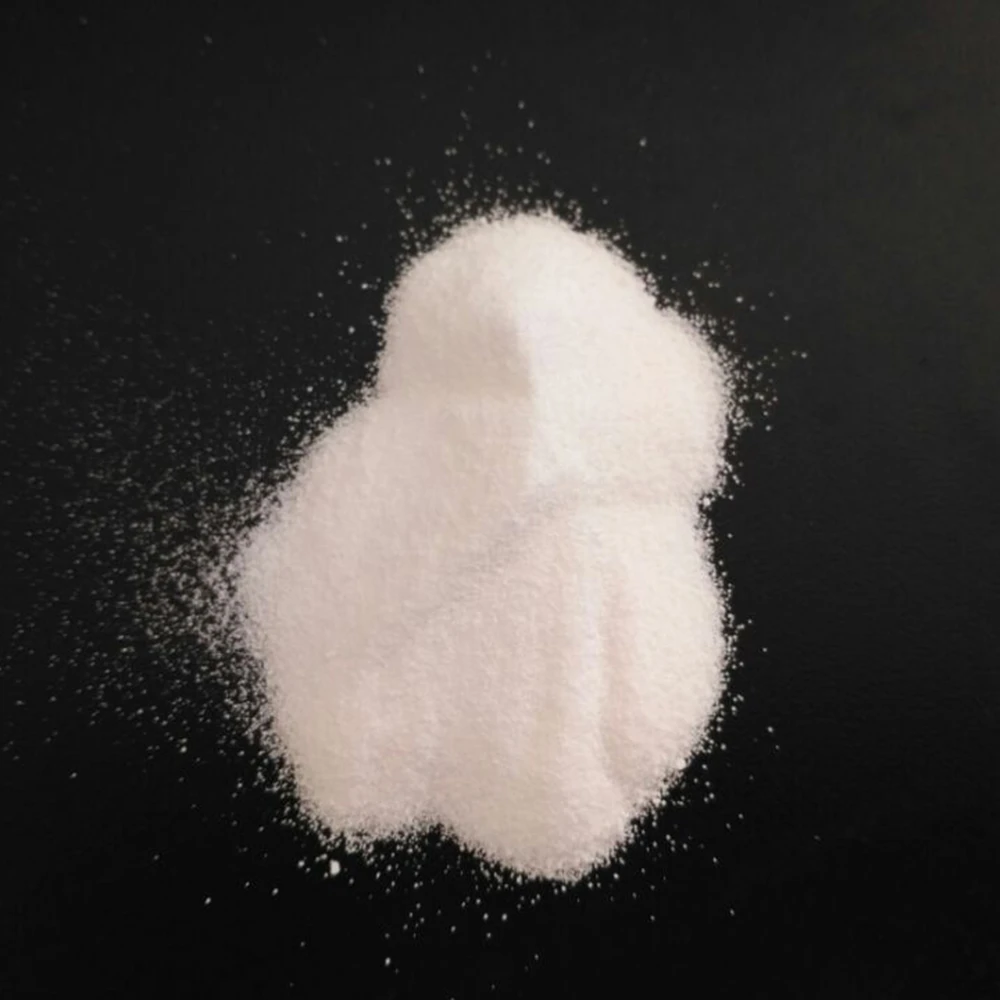

Chlorine Dioxide Generating Powder /Tablet

Mar . 06, 2025 15:26

Back to list

Chlorine Dioxide Generating Powder /Tablet

In the world of chemicals, chlorine dioxide is a compound that garners attention for its powerful oxidizing and disinfecting capabilities. Known for its broad spectrum of applications, the compound is used in water treatment, food processing, and even in the medical field for sterilization purposes. However, like any potent chemical, chlorine dioxide requires cautious handling and a deep understanding of its properties. This is where the chlorine dioxide liquid Safety Data Sheet (SDS) becomes indispensable for both manufacturers and users.

Authoritativeness with a chemical like chlorine dioxide stems from research and adherence to regulatory standards. Agencies such as the Occupational Safety and Health Administration (OSHA) in the United States set forth guidelines and requirements for the proper handling and storage of hazardous substances. These regulations are mirrored in an SDS, making it a legally authoritative document. Professionals and companies that manufacture or utilize chlorine dioxide will often rely on certified industrial hygienists to ensure they are in full compliance with these standards, thus reinforcing the authoritative aspect of the SDS in a working environment. Trustworthiness is paramount when dealing with chemicals, and the chlorine dioxide SDS is a cornerstone document in establishing this trust. Companies and laboratories depend on accurate and up-to-date SDSs to not only protect their employees but also ensure their operational integrity. A trustworthy SDS will list all potential hazards, provide clear preventative measures, and offer solutions for emergency situations, thus ensuring a safe working environment. Manufacturers providing chlorine dioxide must ensure that their SDSs are regularly updated following any new research or regulatory changes, maintaining their reliability and relevance. The role of chlorine dioxide in various industries cannot be understated, yet it comes with its challenges. Understanding the chlorine dioxide liquid SDS helps bridge the gap between potential risk and practical application. It is a testament to the importance of safety-focused documentation that aids in the educated use of chemicals while fostering a culture of safety and compliance. With these principles in place, the SDS not only serves as a guide but as a protector, ensuring that both people and environments remain safeguarded against potential chemical hazards.

Authoritativeness with a chemical like chlorine dioxide stems from research and adherence to regulatory standards. Agencies such as the Occupational Safety and Health Administration (OSHA) in the United States set forth guidelines and requirements for the proper handling and storage of hazardous substances. These regulations are mirrored in an SDS, making it a legally authoritative document. Professionals and companies that manufacture or utilize chlorine dioxide will often rely on certified industrial hygienists to ensure they are in full compliance with these standards, thus reinforcing the authoritative aspect of the SDS in a working environment. Trustworthiness is paramount when dealing with chemicals, and the chlorine dioxide SDS is a cornerstone document in establishing this trust. Companies and laboratories depend on accurate and up-to-date SDSs to not only protect their employees but also ensure their operational integrity. A trustworthy SDS will list all potential hazards, provide clear preventative measures, and offer solutions for emergency situations, thus ensuring a safe working environment. Manufacturers providing chlorine dioxide must ensure that their SDSs are regularly updated following any new research or regulatory changes, maintaining their reliability and relevance. The role of chlorine dioxide in various industries cannot be understated, yet it comes with its challenges. Understanding the chlorine dioxide liquid SDS helps bridge the gap between potential risk and practical application. It is a testament to the importance of safety-focused documentation that aids in the educated use of chemicals while fostering a culture of safety and compliance. With these principles in place, the SDS not only serves as a guide but as a protector, ensuring that both people and environments remain safeguarded against potential chemical hazards.

Latest news

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025