Suppliers of Chemicals for Cooling Tower Maintenance and Water Treatment Solutions

The Importance of Chemical Suppliers in Cooling Tower Maintenance

Cooling towers are essential components of various industrial processes, providing efficient heat exchange and ensuring optimal operation of systems such as HVAC, power plants, and manufacturing processes. To maintain the efficiency and longevity of cooling towers, proper water treatment is crucial, and this is where cooling tower chemical suppliers come into play. These suppliers provide specialized chemicals and solutions designed to prevent scaling, corrosion, and biological growth, which are vital for the effective operation of cooling towers.

Understanding Cooling Towers

Before diving into the role of chemical suppliers, it's important to understand what cooling towers do. Essentially, cooling towers dissipate heat from a liquid to the atmosphere through the cooling of a stream of water. They function on the principles of evaporation and convection. As water circulates through the system, it absorbs heat from the machinery and is then cooled through the tower before being recirculated. However, the recirculation process can lead to the buildup of minerals, algae, and other contaminants that can compromise system efficiency.

The Role of Chemicals in Cooling Tower Management

To combat the issues associated with this buildup, cooling tower chemical suppliers offer a range of products tailored for water treatment. These chemicals include

1. Scale Inhibitors Hard water minerals such as calcium and magnesium can precipitate and form scale, which can reduce heat exchange efficiency. Scale inhibitors work by binding to these minerals, preventing them from crystallizing and depositing on heat exchange surfaces.

2. Corrosion Inhibitors Metal components within cooling towers are prone to corrosion, particularly in the presence of oxygen and other aggressive agents. Corrosion inhibitors create a protective barrier on metal surfaces, minimizing the risk of deterioration and extending the lifespan of equipment.

3. Biocides Biological growth such as algae and bacteria can cause fouling and increase the risk of Legionnaires’ disease. Biocides are crucial in controlling these organisms, helping to maintain water quality and system efficiency.

4. pH Adjusters Maintaining the proper pH level of water is essential for preventing scale and corrosion. Chemical suppliers provide acids or alkalizing agents to ensure the water remains within an optimal range.

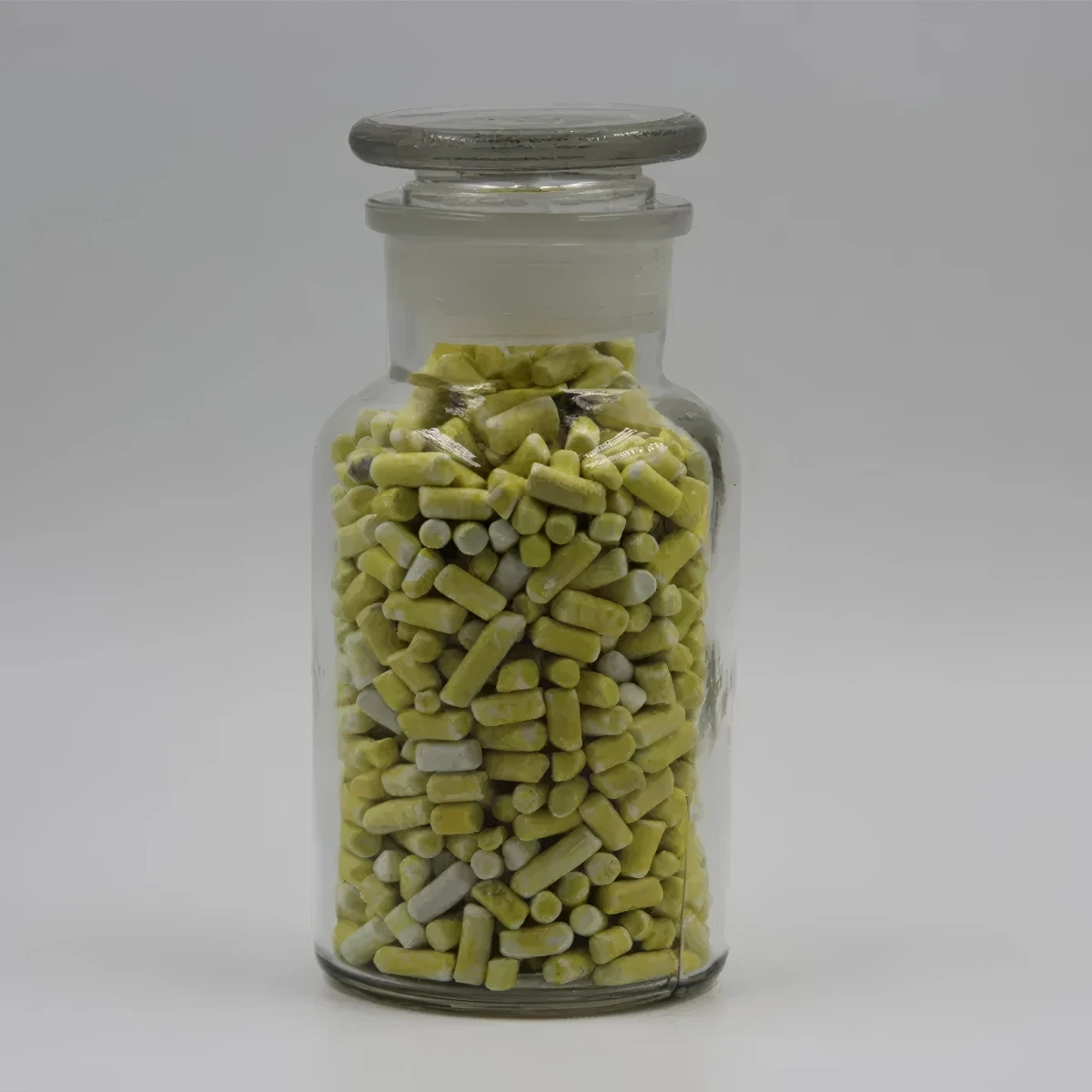

cooling tower chemical suppliers

5. Dispersants These chemicals help prevent the agglomeration of particles, which can lead to deposits and fouling within the system.

Choosing the Right Supplier

When selecting a cooling tower chemical supplier, there are several factors to consider. Reliability and experience in the industry are paramount. A reputable supplier should provide not only high-quality products but also technical support and guidance in the application of their chemicals.

Moreover, understanding the specific needs of your cooling tower system is critical. Factors such as water chemistry, operational conditions, and environmental regulations can impact the selection of chemicals. A good supplier will offer tailored solutions based on these unique requirements.

Sustainability is also an increasingly important consideration. Many suppliers now offer eco-friendly products that minimize environmental impact while effectively managing water quality. Seeking suppliers with a commitment to sustainable practices can benefit both the cooling tower operation and the broader environment.

Trends in Cooling Tower Chemical Supply

The landscape of cooling tower chemical supply is evolving, driven by advancements in technology and an increasing focus on environmental sustainability. New formulations and delivery methods are being developed, improving the efficiency and effectiveness of water treatment.

Additionally, the rise of digital monitoring and automation in industrial settings has led to improvements in how cooling tower operations are managed. Suppliers are beginning to offer services that include remote monitoring of water chemistry, allowing for real-time adjustments and proactive maintenance, which can greatly enhance the reliability and efficiency of cooling systems.

Conclusion

The role of cooling tower chemical suppliers extends far beyond merely providing chemicals. They are essential partners in ensuring that cooling towers operate efficiently, safely, and sustainably. By understanding the importance of proper chemical management and choosing the right supplier, industries can significantly enhance their operational efficiency, reduce downtime, and prolong the lifespan of their cooling systems. As technology advances and environmental considerations gain importance, the relationship between cooling tower systems and chemical suppliers will continue to evolve, shaping the future of industrial water treatment.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025