Making Saltpeter

Making Saltpeter A Historical Overview

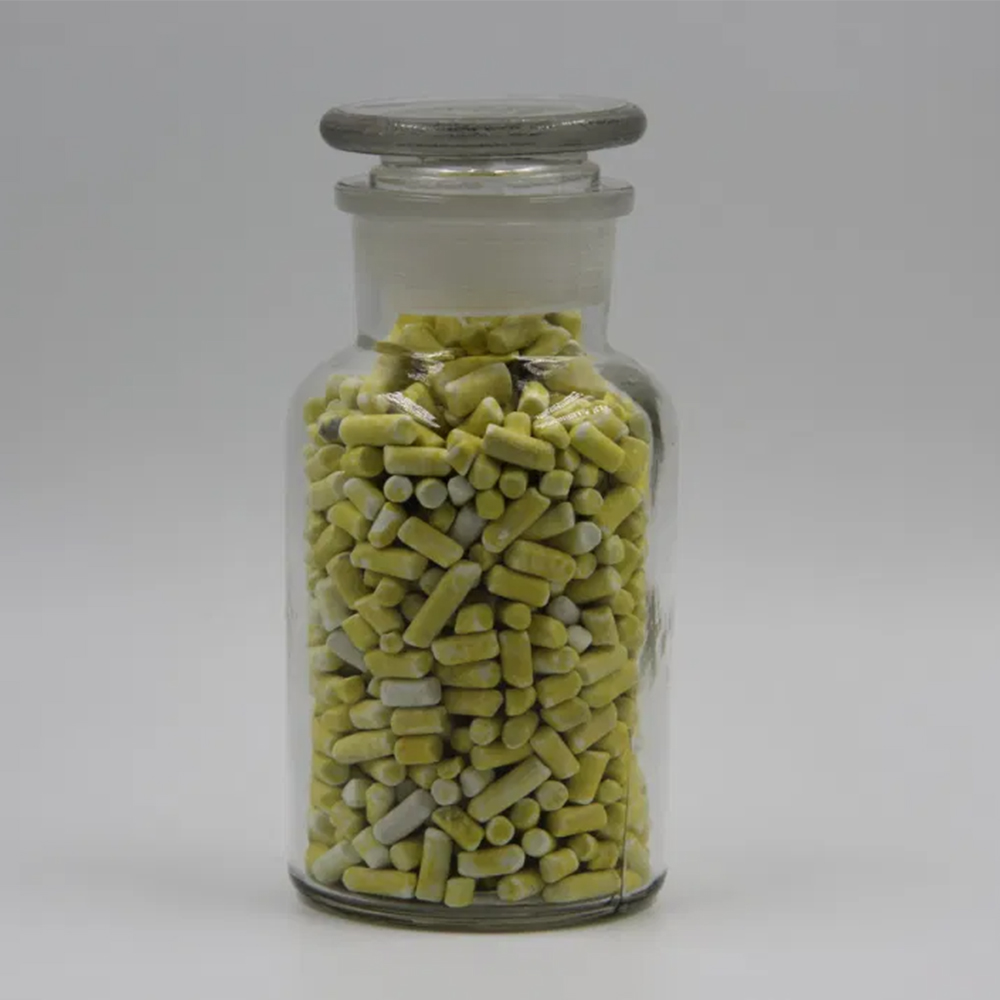

Saltpeter, scientifically known as potassium nitrate (KNO3), has been an essential compound throughout history, primarily used in gunpowder production, fertilizers, and food preservation. The interest in making saltpeter stems from both its practical applications and its fascinating historical significance.

Historically, the process of making saltpeter dates back to ancient civilizations. The earliest references can be found in texts from the Byzantine Empire, where it was utilized in the production of fireworks and military explosives. By the medieval period, saltpeter was a crucial ingredient in gunpowder, marking a significant turning point in warfare and technology.

The traditional method of producing saltpeter is a labor-intensive process that often involves the decomposition of organic materials. Typically, the essential ingredients include animal manure, plant matter, and soil. The process generally takes place in a pit where these materials are combined and left to decay over time. As the organic matter breaks down, nitrogen compounds are released, which then reacts with potassium-containing minerals present in the soil.

To extract saltpeter, the resulting mixture is leached with water. This means that water is poured over the decomposed materials, dissolving the soluble salts, including potassium nitrate. The liquid is then collected and evaporated, typically in earthenware vessels or on flat surfaces under the sun. As the water evaporates, saltpeter crystallizes and can be collected. This simple yet effective process highlights the ingenuity of early chemists, long before the advent of modern science.

making saltpeter

The 19th century brought about advancements in the understanding of chemical processes. With the industrial revolution, the demand for saltpeter surged, particularly for military applications. As a result, the production scaled up with factory processes, making it more accessible and affordable. However, the basic principles remained rooted in the age-old techniques of leaching and evaporation.

In contemporary times, most commercial saltpeter is synthesized through chemical processes rather than relying on the traditional methods. While the chemical conversion from sodium nitrate to potassium nitrate is efficient, the historical methods are still appreciated for their role in the development of early chemistry and industry.

Saltpeter remains relevant today, particularly in agriculture as a vital fertilizer that provides essential nutrients to plants. It also continues to find applications in the food industry, notably in curing meats and preserving various food items. Moreover, its historical implications keep it a subject of study in the fields of archaeology and history, allowing modern scholars a glimpse into the past and the profound impact this compound had on society.

In conclusion, making saltpeter is a process steeped in history, reflecting human ingenuity and adaptability. From ancient times to modern applications, its significance has persisted, embodying the evolution of both chemistry and industry. Whether for its practical applications or historical legacy, saltpeter remains a fascinating subject worthy of exploration.

-

Why Strontium Carbonate Still MattersNewsJun.06,2025

-

Why BaSO4 MattersNewsJun.06,2025

-

Why Barium Carbonate Still MattersNewsJun.06,2025

-

Strontium Hydroxide: A Versatile Compound for Modern ApplicationsNewsJun.06,2025

-

Strontium Chloride in Daily IndustryNewsJun.06,2025

-

Pure Potassium Nitrate for SaleNewsJun.06,2025

-

What Is Sodium Bisulfate Used For?NewsMay.15,2025