Reverse Osmosis Treatment Chemicals for Efficient Water Purification

Understanding Chemicals Used in Reverse Osmosis Treatment

Reverse osmosis (RO) is a widely used water purification process that employs a semi-permeable membrane to remove impurities and contaminants from water. This method is highly effective in producing high-quality drinking water and is essential in various industries, including food and beverage, pharmaceuticals, and desalination. However, the efficiency of RO systems greatly depends on the use of specific treatment chemicals, which play a crucial role in optimizing the process and ensuring the longevity of the RO membranes.

Understanding Chemicals Used in Reverse Osmosis Treatment

Another essential category of chemicals is cleaning agents. Even with preventative measures in place, RO membranes can still become fouled with organic matter, biofilms, and other contaminants over time. Specialized cleaning agents are formulated to effectively remove these foulants without damaging the membrane material. These cleaning solutions typically contain surfactants, acids, or alkaline substances, tailored to the specific types of contaminants present in the feed water.

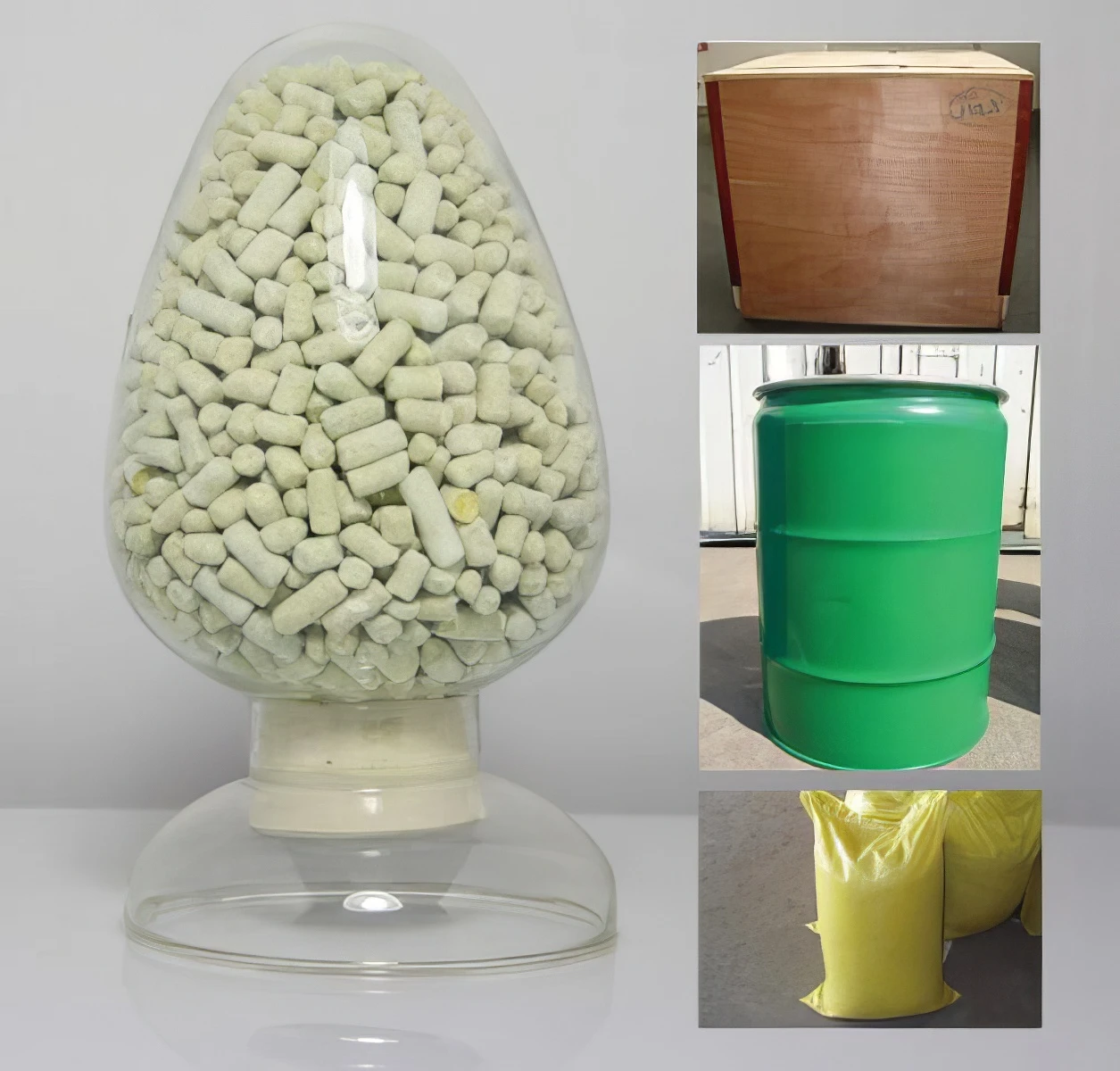

reverse osmosis treatment chemicals

pH control chemicals are also pivotal in RO processes. Maintaining the appropriate pH level is crucial, as it influences the solubility of various minerals and the overall efficacy of the treatment. Adjusting the pH can enhance the performance of antiscalants and cleaning agents, ensuring that the membrane operates efficiently. Commonly used pH adjusters include citric acid and sodium hydroxide, which help in maintaining the desired pH range.

In addition to these, biocides are often employed to control microbial growth in the RO system. If left unchecked, bacteria and other microorganisms can form biofilms on the membranes, leading to fouling and reduced performance. Biocides are utilized during both initial system cleaning and ongoing maintenance to ensure that the water remains free of harmful pathogens.

Finally, coagulates and flocculants may be added to the feed water to aid in the removal of suspended solids before the water reaches the RO membranes. By aggregating small particles into larger clusters, these chemicals enhance the overall filtration process and protect the membranes from damage caused by particulates.

In conclusion, the use of chemicals in reverse osmosis treatment is critical for ensuring the efficiency and longevity of the purification process. From antiscalants and cleaning agents to pH control chemicals and biocides, each plays a vital role in optimizing the performance of RO systems and providing safe, high-quality water for various applications. Understanding these chemicals and their functions enables better maintenance and operation of reverse osmosis systems, ultimately leading to improved water quality and reduced operational costs.

-

Why Strontium Carbonate Still MattersNewsJun.06,2025

-

Why BaSO4 MattersNewsJun.06,2025

-

Why Barium Carbonate Still MattersNewsJun.06,2025

-

Strontium Hydroxide: A Versatile Compound for Modern ApplicationsNewsJun.06,2025

-

Strontium Chloride in Daily IndustryNewsJun.06,2025

-

Pure Potassium Nitrate for SaleNewsJun.06,2025

-

What Is Sodium Bisulfate Used For?NewsMay.15,2025