Safety Data Sheet for Sodium Sulfide Handling and Storage Guidelines

Understanding Sodium Sulphide A Comprehensive Guide

Sodium sulphide (Na2S) is an inorganic compound that is extensively used across various industries, from chemical manufacturing to pulp and paper production. This article aims to provide an in-depth overview of sodium sulphide, including its properties, uses, safety considerations, and environmental impact.

Properties of Sodium Sulphide

Sodium sulphide appears as a yellow to reddish solid that is soluble in water. It has a characteristic rotten egg smell due to the release of hydrogen sulphide gas upon contact with moisture. Sodium sulphide has a molecular weight of 78.04 g/mol and a melting point of approximately 1,800 °C (3,272 °F). The compound is highly reactive, especially when interacting with water or acids, which can lead to the release of toxic gases.

Chemically, sodium sulphide consists of two sodium (Na) ions and one sulphide (S^2-) ion. Its strong alkaline nature makes it a useful reagent in various chemical reactions. In solution, it acts as a strong reducing agent, which makes it valuable in numerous applications, including the production of dyes, pharmaceuticals, and other chemicals.

Industrial Uses

One of the primary applications of sodium sulphide is in the paper industry, where it is used in the Kraft process for wood pulping. It reacts with lignin in wood, breaking it down and allowing for the separation of cellulose fibers. This process is vital for producing high-quality paper products.

In the textile industry, sodium sulphide is employed in the dyeing process, particularly for dyeing cotton and other cellulose fibers. Its ability to form soluble complexes with various dyes enhances the color uptake, ensuring vibrant and long-lasting finishes.

Sodium sulphide is also used in the mining industry for the extraction of metals such as copper and zinc. It helps in the flotation process, making it easier to separate valuable minerals from ore.

Additionally, sodium sulphide has applications in the manufacture of various chemicals, including phosphors for certain types of lighting, as well as in the production of sodium thiosulphate, a common antidote for cyanide poisoning.

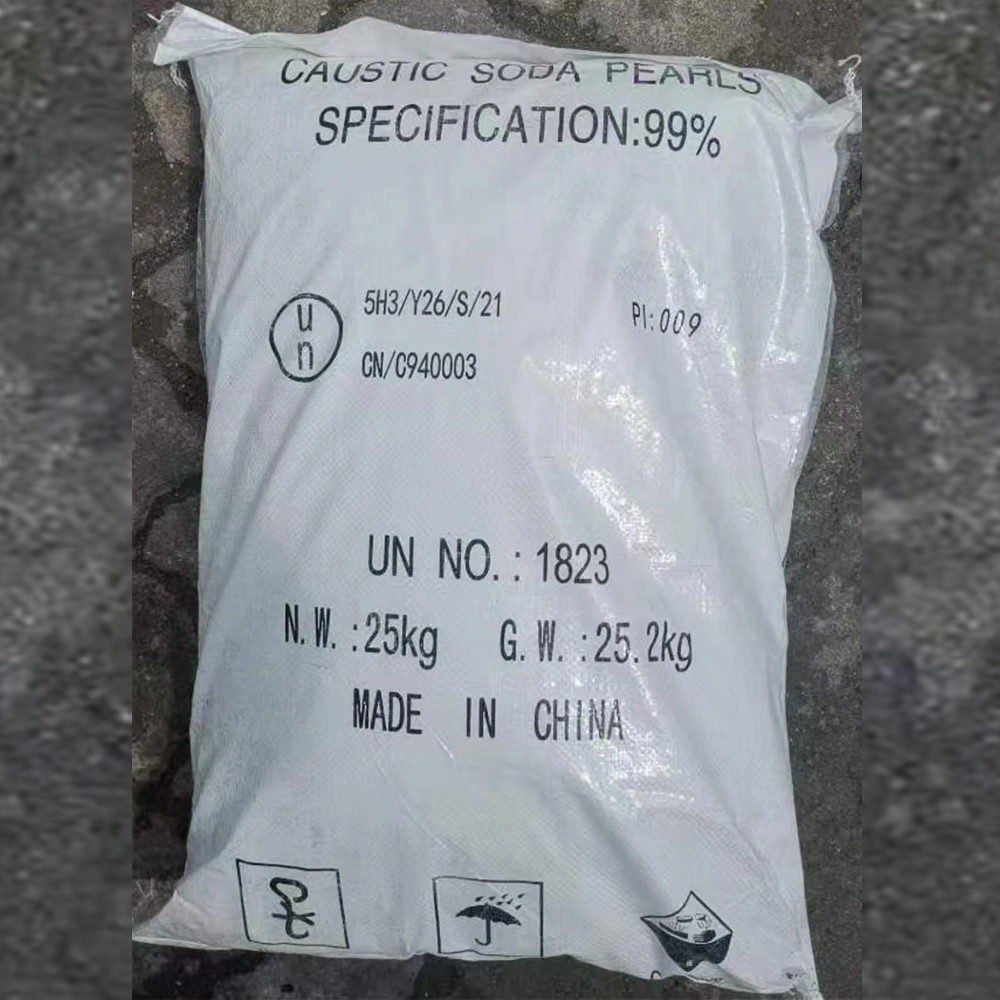

sodium sulphide sds

Safety Considerations

While sodium sulphide is widely used, it also poses various health and safety risks. It is considered hazardous due to its corrosive nature, which can lead to severe injuries upon contact with skin or eyes. Inhalation of its dust or vapors can result in respiratory irritation, while ingestion may lead to severe gastrointestinal distress.

Safety Data Sheets (SDS) for sodium sulphide emphasize the importance of personal protective equipment (PPE) when handling this substance. Recommended PPE includes gloves, goggles, and protective clothing. In case of spills, proper containment measures must be taken to minimize exposure and environmental impact.

Environmental Impact

The use of sodium sulphide raises concerns regarding its environmental impact. Discharges containing sodium sulphide can lead to soil and water contamination, as it can produce hydrogen sulphide gas, a toxic material harmful to aquatic life. Consequently, industries must adhere to strict regulations and guidelines to ensure that sodium sulphide is handled and disposed of properly.

Efforts are being made to develop more environmentally friendly alternatives to sodium sulphide, particularly in the pulp and paper sector. Innovations in chemical processes seek to reduce the reliance on harmful substances while maintaining efficiency and effectiveness.

Conclusion

Sodium sulphide is a versatile compound with significant industrial applications. From its role in wood pulping to its use in dyeing and metal extraction, sodium sulphide is integral to many manufacturing processes. Nonetheless, it poses risks to human health and the environment, necessitating careful handling and monitoring.

Understanding the properties, uses, and hazards associated with sodium sulphide is crucial for industries engaged in its application. As we strive toward more sustainable practices, finding safe alternatives and enhancing the management of hazardous substances will be fundamental in balancing industrial needs with environmental protection.

-

Using Potassium Nitrate for Colorants in Various ProductsNewsApr.29,2025

-

Safety Precautions When Handling Monopotassium PhosphateNewsApr.29,2025

-

Lead Oxide in Wastewater Treatment: A Powerful SolutionNewsApr.29,2025

-

Innovations in Sodium Chlorite ApplicationsNewsApr.29,2025

-

How Lead Nitrate is Used in Analytical ChemistryNewsApr.29,2025

-

Different Grades of Sodium Bisulfate: Which One Do You Need?NewsApr.29,2025

-

Sodium Chlorite vs. Other Disinfectants: A Comparative AnalysisNewsApr.14,2025