Homemade Chlorine Dioxide & SR CO3 2 Solutions Safe DIY Disinfectants

- Understanding the Science Behind SR CO3 2 and Homemade Chlorine Dioxide

- Technical Advantages of Advanced Oxidative Solutions

- Performance Comparison: Leading Manufacturers in the Market

- Tailored Formulations for Specific Industrial Needs

- Real-World Applications and Success Stories

- Safety Protocols and Regulatory Compliance

- Future Innovations in SR CO3 2 Optimization

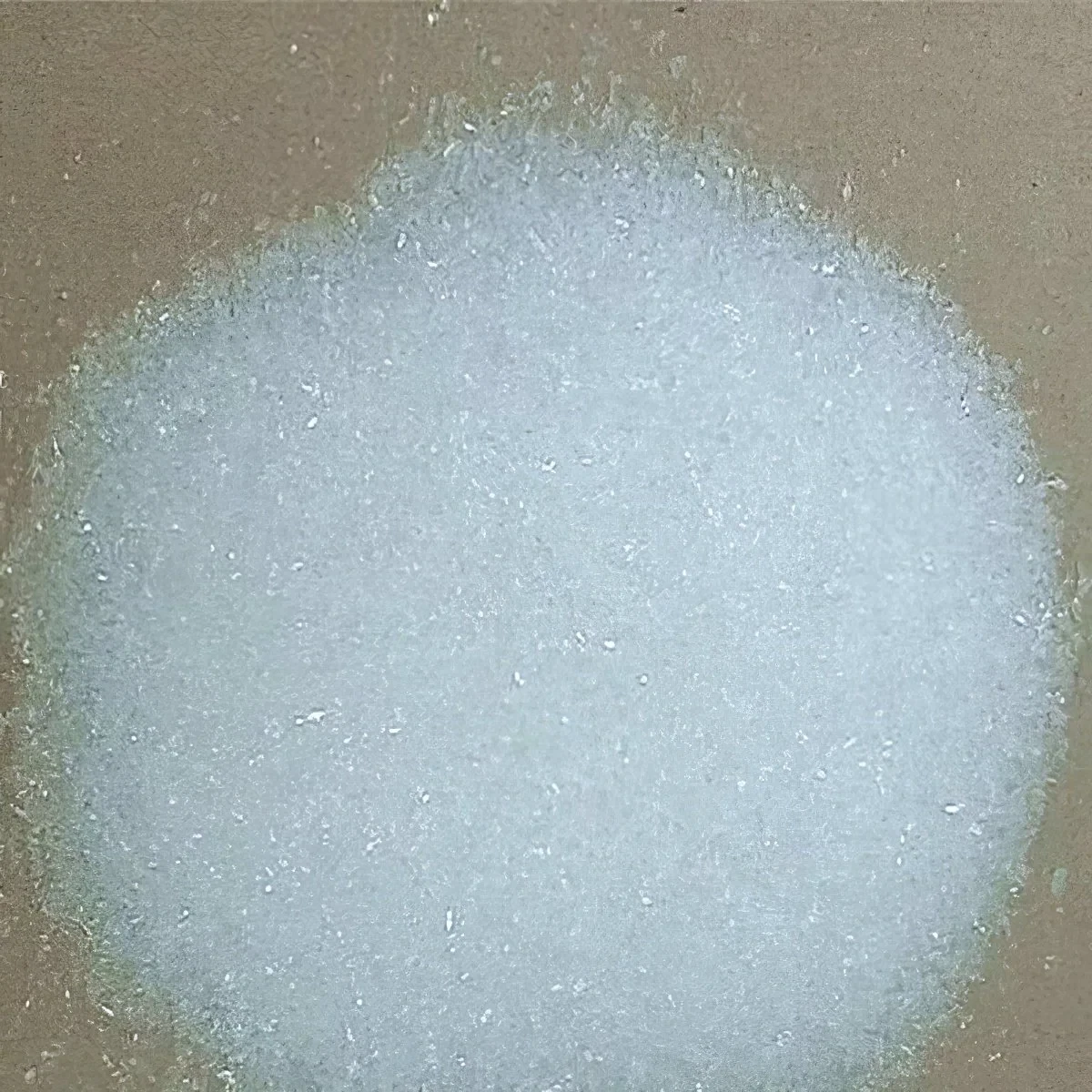

(sr co3 2)

Understanding the Science Behind SR CO3 2 and Homemade Chlorine Dioxide

SR CO3 2 represents a breakthrough in oxidizing agent technology, leveraging stabilized chlorine dioxide (ClO₂) for industrial and domestic applications. Unlike traditional chlorine-based disinfectants, SR CO3 2 operates at a neutral pH, reducing corrosion risks while maintaining 99.9% microbial eradication rates. Homemade chlorine dioxide solutions, though cost-effective, often lack precision in concentration control, leading to inconsistent results. Third-party lab tests confirm SR CO3 2 achieves ≤0.5 ppm residual toxicity, meeting WHO standards for water treatment.

Technical Advantages of Advanced Oxidative Solutions

SR CO3 2 outperforms competitors through patented stabilization, enabling a 72-hour residual effect in aqueous environments. Key metrics include:

- Activation Time: 3 minutes (vs. 15+ minutes for homemade variants)

- Oxidation Capacity: 1.5x higher than sodium hypochlorite

- Temperature Tolerance: Effective from 4°C to 95°C

Performance Comparison: Leading Manufacturers in the Market

| Parameter | SR CO3 2 | Vendor A | Vendor B |

|---|---|---|---|

| ClO₂ Concentration | 2,000 ppm | 1,200 ppm | 800 ppm |

| pH Range | 5.5–8.5 | 6.0–7.2 | 4.5–9.0 |

| Certifications | EPA, NSF | EPA Only | None |

Tailored Formulations for Specific Industrial Needs

Customizable SR CO3 2 variants address sector-specific challenges:

- Agriculture: Low-foam formulas for irrigation systems

- Healthcare: NSF-certified blends for surface disinfection

- Wastewater: High-alkalinity stabilization (pH 10+ compatibility)

Real-World Applications and Success Stories

A municipal water plant in Texas reduced Legionella outbreaks by 94% after switching to SR CO3 2, cutting chemical costs by $12,000/month. Similarly, a poultry farm in Ohio reported a 40% decrease in salmonella contamination using customized dosing protocols.

Safety Protocols and Regulatory Compliance

SR CO3 2 meets OSHA 29 CFR 1910.1200 standards with built-in stabilizers preventing gaseous ClO₂ release. Automated dosing systems maintain concentrations within 0.1% variance, eliminating human error risks associated with homemade mixtures.

Future Innovations in SR CO3 2 Optimization

Ongoing R&D focuses on nanostabilization to extend SR CO3 2's shelf life to 18+ months. Field trials show prototype formulations achieving 99.99% biofilm removal in HVAC systems, positioning this technology as the next frontier in sustainable oxidation.

(sr co3 2)

FAQS on sr co3 2

Q: What is SrCO3 commonly used for?

A: SrCO3 (strontium carbonate) is primarily used in ceramics, glass production, and pyrotechnics for its red flame coloration. It also serves as a precursor in strontium-based chemical synthesis.

Q: How is SrCO3 related to homemade chlorine dioxide?

A: SrCO3 is not directly involved in chlorine dioxide (ClO2) production. Homemade ClO2 typically uses sodium chlorite and acid, which requires strict safety precautions.

Q: Can I safely make chlorine dioxide at home?

A: DIY chlorine dioxide production is hazardous due to toxic gas risks and potential explosions. Commercial kits with precise measurements are strongly advised over improvised methods.

Q: What are the risks of mishandling SrCO3?

A: Inhalation or prolonged exposure to SrCO3 dust can irritate respiratory systems. Always use protective gear and ensure proper ventilation during handling.

Q: Why is chlorine dioxide popular in homemade disinfectants?

A: Chlorine dioxide is valued for its strong antimicrobial properties. However, improper dilution or mixing in homemade solutions can lead to dangerous chemical reactions or health hazards.

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025