Sodium Isopropyl Xanthate (SIPX): Premium Mineral Flotation Reagent

Introduction to Xanthate Flotation Reagents

In the intricate world of mineral processing, effective separation techniques are paramount to extracting valuable resources efficiently. Among the most critical reagents employed for this purpose are xanthates, a class of organic compounds widely recognized for their efficacy as collectors in froth flotation. This article centers on sodium isopropyl xanthate, a powerful and versatile chemical compound extensively used in the mining industry. Understanding its technical specifications, application advantages, and comprehensive supply chain aspects is crucial for B2B decision-makers seeking optimized mineral recovery and operational efficiency.

Sodium isopropyl xanthate is a vital component in the flotation of various sulfide minerals, including copper, lead, zinc, and nickel, as well as in the recovery of precious metals like gold. Its unique chemical structure allows it to selectively adhere to the surface of target minerals, rendering them hydrophobic and enabling their separation from gangue material via froth flotation. This selective action is key to achieving high-grade concentrates and maximizing resource utilization in a cost-effective manner.

Industry Trends in Mining Chemicals

The `mining chemicals` sector is experiencing dynamic shifts driven by several key global trends. Resource scarcity and decreasing ore grades compel the industry to adopt more efficient and selective flotation reagents, such as sodium isopropyl xanthate, to maintain economic viability. Furthermore, stringent environmental regulations are pushing for the development and use of more eco-friendly and biodegradable chemicals, reducing the ecological footprint of mining operations.

Digitalization and automation are also transforming mineral processing, leading to smarter dosing systems and real-time process optimization for `mining chemicals`. This ensures precise application of collectors like sodium isopropyl xanthate, minimizing reagent consumption and maximizing recovery rates. The demand for robust supply chains and localized manufacturing capabilities is also growing, addressing geopolitical uncertainties and ensuring consistent availability of critical reagents. Innovation in collector chemistry, focusing on enhanced selectivity and reduced dosage, remains a primary driver for R&D in this specialized market. According to recent market analysis, the global mineral processing chemicals market is projected to grow significantly, with a CAGR of over 4% from 2022 to 2030, highlighting the increasing importance of advanced solutions like xanthates in achieving sustainable mining practices.

Manufacturing Process Flow of Sodium Isopropyl Xanthate

The manufacturing of sodium isopropyl xanthate (SIPX) is a carefully controlled chemical synthesis process, ensuring high purity and consistent performance critical for its application in mineral flotation. The general process involves the reaction of isopropyl alcohol, carbon disulfide, and sodium hydroxide.

Process Flow Overview:

- Raw Material Preparation: High-grade isopropanol (isopropyl alcohol), carbon disulfide (CS2), and sodium hydroxide (NaOH) solution are prepared and measured according to precise stoichiometric ratios. Quality control checks (e.g., purity of isopropanol, concentration of NaOH) are performed at this stage.

-

Xanthation Reaction: The reaction typically takes place in a jacketed stainless-steel reactor equipped with agitators and cooling coils. Sodium hydroxide is first dissolved in water to form a solution. Isopropanol is then added to the reactor. Carbon disulfide is slowly introduced into the mixture under controlled temperature (typically between 20-40°C) and pressure to ensure a safe and efficient exothermic reaction. The reaction proceeds as follows:

CH₃CH(OH)CH₃ + CS₂ + NaOH → CH₃CH(OCS₂)CH₃Na⁺ + H₂O (Isopropanol + Carbon Disulfide + Sodium Hydroxide → Sodium Isopropyl Xanthate + Water) - Purification and Filtration: After the reaction is complete, the crude sodium isopropyl xanthate solution may contain impurities. These are removed through filtration, often using fine mesh filters or centrifuges, to ensure the desired purity and remove any unreacted raw materials or by-products.

- Drying: The purified solution is then subjected to a drying process. This can be achieved through various methods such as spray drying, vacuum drying, or drum drying, which remove water content and yield a solid product, typically in granular or pellet form. The moisture content is carefully monitored to meet product specifications.

- Packaging: The dried sodium isopropyl xanthate product is then packaged into specialized drums or bags, typically lined to prevent moisture absorption and ensure long-term stability. Packaging adheres to international standards for hazardous materials transport.

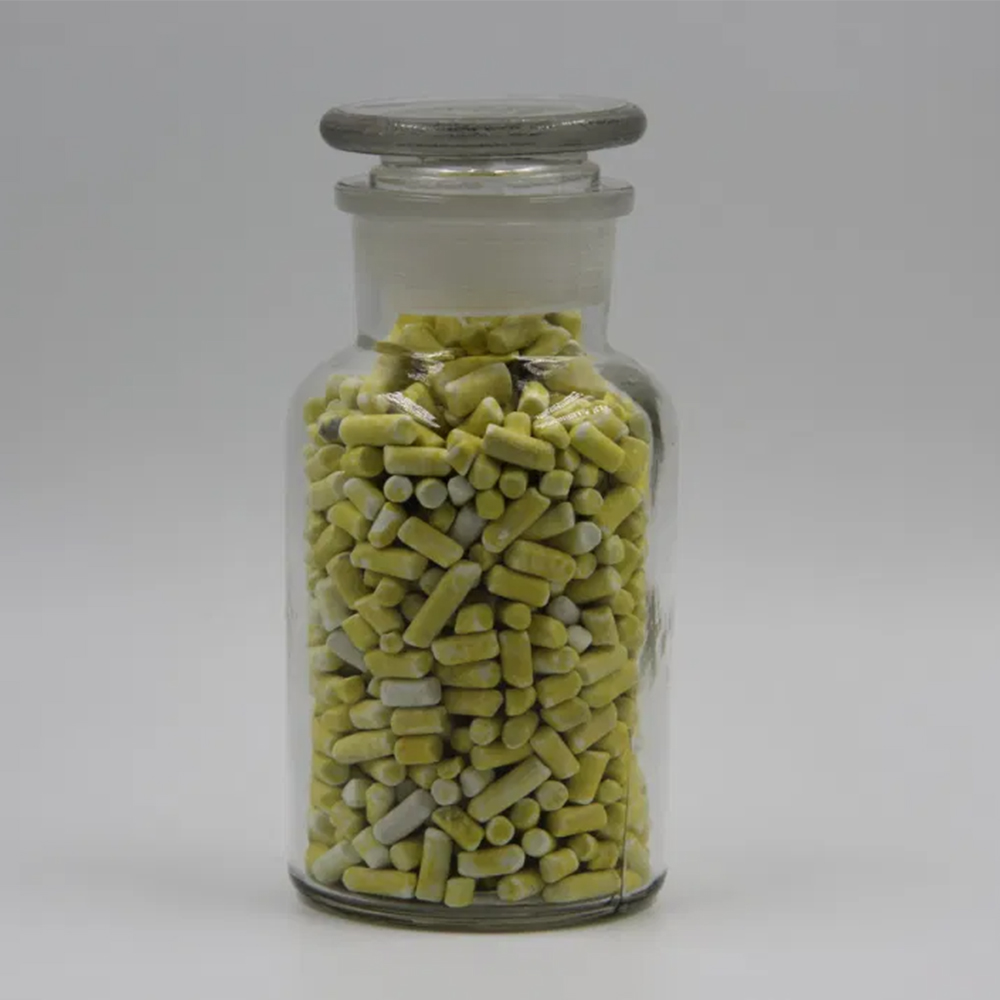

Figure 1: Typical manufacturing setup for producing sodium isopropyl xanthate (Illustrative).

Testing Standards and Quality Assurance: Throughout the manufacturing process, strict quality control measures are implemented. Products are tested against international standards such as ISO 9001 for quality management and specific chemical purity standards (e.g., GB/T for industrial chemicals). Key parameters checked include active ingredient content, moisture, free alkali, and color. These rigorous checks ensure that the final sodium isopropyl xanthate product exhibits optimal performance and consistency, providing a reliable reagent for target industries such as metallurgy and mineral processing, ensuring advantages like enhanced recovery and reduced energy consumption in flotation circuits.

Technical Specifications and MSDS Information

Understanding the precise technical specifications of sodium isopropyl xanthate is critical for optimal application and safety. This section provides key parameters and refers to the `sodium isopropyl xanthate msds` for comprehensive safety and handling information.

| Parameter | Specification | Test Method / Standard |

|---|---|---|

| Active Ingredient (Purity) | ≥ 90% | Titration Method (e.g., Iodine Titration) |

| Moisture Content | ≤ 5% | Drying Method (e.g., Karl Fischer) |

| Free Alkali (NaOH) | ≤ 0.5% | Acid-Base Titration |

| Appearance | Light yellow to greyish yellow pellets/powder | Visual Inspection |

| Solubility | Soluble in water, slightly soluble in ethanol | Solubility Test |

| Decomposition Temperature | Approx. 120-130°C | Thermal Analysis (e.g., TGA) |

| pH (10% aqueous solution) | 9-11 | pH Meter |

For comprehensive information regarding safe handling, storage, emergency procedures, and environmental considerations, users should always refer to the specific `sodium isopropyl xanthate msds` provided by the supplier. The MSDS (Material Safety Data Sheet) outlines critical data points such as flash point, auto-ignition temperature, toxicity data, first-aid measures, and disposal recommendations, which are indispensable for maintaining a safe operational environment. Adherence to these guidelines is crucial for protecting personnel and minimizing environmental impact.

Application Scenarios for Sodium Isopropyl Xanthate

Sodium isopropyl xanthate is a highly effective and widely utilized collector in various mineral processing applications, particularly in the froth flotation of sulfide minerals and certain oxide ores. Its versatility and strong collecting power make it indispensable in modern metallurgical operations.

Typical Application Areas:

- Sulfide Mineral Flotation: SIPX is primarily used in the flotation of sulfide ores of copper (chalcopyrite, bornite), lead (galena), zinc (sphalerite, after activation), nickel (pentlandite), and iron sulfides (pyrite, pyrrhotite). Its robust collecting action ensures high recovery rates even from complex or finely disseminated ores. It exhibits excellent selectivity for copper and lead sulfides over iron sulfides, aiding in the production of high-grade concentrates.

- Gold and Silver Recovery: In the processing of gold and silver ores, especially those associated with sulfide minerals, sodium isopropyl xanthate acts as an effective collector. It helps in the recovery of free gold and silver, as well as gold and silver encapsulated within sulfide matrices, contributing to enhanced precious metal yield.

- Refractory Ores: For refractory gold and silver ores that are challenging to process, SIPX can be used in combination with other reagents to improve flotation performance. Its chemical stability and strong adsorption characteristics assist in rendering these difficult-to-float minerals hydrophobic.

- Coal Flotation: In certain coal beneficiation processes, xanthates can be utilized to separate high-ash coal from cleaner coal fractions, improving the quality of the final coal product.

Demonstrated Advantages in Applications:

- High Recovery Rates: SIPX’s strong collecting power directly translates to higher recovery percentages of target minerals, increasing overall production efficiency and profitability.

- Improved Selectivity: When properly dosed and combined with depressants, sodium isopropyl xanthate can achieve excellent selectivity, minimizing the co-flotation of unwanted gangue minerals and producing cleaner concentrates. This is crucial for downstream metallurgical processes.

- Cost-Effectiveness: Despite being a specialized chemical, SIPX offers a favorable cost-to-performance ratio due to its potent collecting capabilities, often allowing for lower dosage rates compared to less effective collectors, leading to `energy saving` in reagent consumption and overall operational costs.

- Operational Stability: SIPX performs consistently across a range of pH conditions typical in mineral flotation circuits, contributing to process stability and reducing the need for frequent adjustments.

Technical Advantages of Sodium Isopropyl Xanthate

Beyond its broad application, sodium isopropyl xanthate offers distinct technical advantages that distinguish it as a preferred collector in many mineral processing operations. These advantages contribute significantly to both the efficiency and economic viability of flotation circuits.

- Superior Collecting Power: SIPX exhibits robust affinity for sulfide mineral surfaces, forming a strong chemisorbed layer. This strong interaction ensures excellent hydrophobicity, allowing minerals to readily attach to air bubbles and float. This characteristic makes it highly effective for finely disseminated ores, which are often challenging to process.

- Enhanced Selectivity: Compared to some other xanthates or dithiophosphates, sodium isopropyl xanthate offers a balanced selectivity. It is highly effective for primary sulfide minerals while allowing for differential flotation with proper depressant schemes, especially for complex polymetallic ores containing copper, lead, and zinc. This reduces cross-contamination, yielding higher-grade concentrates.

- Excellent Stability in Solution: SIPX maintains good stability in aqueous solutions under typical flotation conditions (pH 7-11), minimizing decomposition and ensuring consistent performance over the retention time in flotation cells. This contributes to reliable and predictable flotation kinetics.

- Broader pH Operating Range: While optimal performance is typically achieved in neutral to alkaline circuits, sodium isopropyl xanthate can tolerate a relatively broader pH range compared to other collectors, providing flexibility in process design and adaptation to varying ore body chemistries.

- Improved Concentrate Grade: By promoting selective recovery and minimizing gangue entrainment, the use of SIPX often results in higher-grade mineral concentrates, which can significantly reduce downstream processing costs and improve overall metallurgical efficiency.

These technical attributes underscore why sodium isopropyl xanthate remains a cornerstone reagent for efficient and effective sulfide mineral flotation, directly contributing to `energy saving` through optimized reagent consumption and higher throughput.

Vendor Comparison and Customized Solutions

When selecting `sodium isopropyl xanthate suppliers`, discerning B2B buyers prioritize not only product quality but also reliability, technical support, and the ability to offer customized solutions. A robust vendor partnership can significantly impact operational efficiency and cost-effectiveness.

Key Criteria for Vendor Selection:

- Product Quality and Consistency: The supplier must consistently deliver sodium isopropyl xanthate meeting stringent purity and activity specifications. Certifications such as ISO 9001, combined with robust internal QC/QA protocols, are indicative of a reputable supplier.

- Reliable Supply Chain: A strong logistics network, secure warehousing, and contingency planning are essential to ensure uninterrupted supply, especially for critical `mining chemicals`. A proven track record and global distribution capabilities are significant advantages.

- Technical Support and Expertise: Leading `sodium isopropyl xanthate suppliers` offer comprehensive technical support, including laboratory testing, on-site audits, and expert advice on reagent selection and optimization. This ensures optimal performance for specific ore types and processing conditions.

- Compliance and Safety: Adherence to international environmental, health, and safety (EHS) standards, including detailed `sodium isopropyl xanthate msds` provisions, reflects a responsible and trustworthy partner.

- Years of Service & Client Portfolio: Companies with extensive experience and a diverse portfolio of satisfied, long-term clients demonstrate proven authoritativeness and trustworthiness in the industry.

Customized Solutions:

Recognizing that no two mining operations are identical, leading `sodium isopropyl xanthate suppliers` often provide customized solutions tailored to specific client needs. This can include:

- Tailored Formulations: Adjusting the concentration of sodium isopropyl xanthate, or combining it with other reagents (e.g., frothers, depressants) to create bespoke formulations that achieve optimal selectivity and recovery for a particular ore body.

- Flexible Packaging and Delivery: Offering various packaging sizes (e.g., drums, bulk bags, or even liquid solutions for specialized applications) and delivery schedules to meet operational requirements and optimize logistics.

- Process Optimization Support: Collaborating with clients to conduct pilot plant tests and full-scale plant trials, providing data-driven recommendations for dosage, addition points, and overall circuit optimization to maximize the performance of sodium isopropyl xanthate.

This bespoke approach ensures that clients receive not just a product, but a complete solution designed to enhance their specific mineral processing challenges.

Application Case Studies

The practical effectiveness of sodium isopropyl xanthate is best demonstrated through real-world application scenarios, where it has consistently delivered superior results in mineral recovery.

Case Study 1: Copper-Zinc Sulfide Flotation

A major polymetallic mine in South America faced challenges in selectively separating copper and zinc sulfides from a complex ore body. Initial flotation circuits using a combination of other xanthates resulted in sub-optimal copper concentrate grades due to high zinc contamination. After detailed metallurgical testing and collaboration with their `sodium isopropyl xanthate suppliers`, the mine transitioned to a reagent scheme prominently featuring sodium isopropyl xanthate as the primary copper collector, combined with a selective depressant for zinc.

- Result: The implementation of SIPX led to an increase in copper concentrate grade from 22% to 26%, with a simultaneous reduction in zinc content from 8% to below 4%. Copper recovery rates also saw a marginal improvement of 1.5%. This enhancement significantly improved the downstream smelter penalties and overall profitability.

- Experience Highlight: This case exemplifies how the selective collecting power of sodium isopropyl xanthate, when expertly applied, can resolve complex separation challenges in real operational environments, enhancing the economic value of the extracted mineral.

Case Study 2: Gold Recovery from Pyritic Ore

An gold mine processing a heavily pyritic ore in West Africa struggled with low gold recovery rates using conventional collectors. The fine dissemination of gold within the pyrite matrix made selective flotation challenging. The mine engaged with a specialist `mining chemicals` provider to optimize their circuit, introducing sodium isopropyl xanthate at various points in the rougher and scavenger circuits.

- Result: The optimized use of SIPX, particularly in combination with a strong frother, improved gold recovery from 78% to 85% without significantly increasing the pyrite content in the gold concentrate. This was attributed to SIPX's ability to effectively collect fine gold particles and gold associated with pyrite, while maintaining reasonable selectivity.

- Experience Highlight: This case highlights the efficacy of sodium isopropyl xanthate in enhancing recovery of precious metals from challenging ore types, directly impacting the mine's overall output and profitability.

Ensuring Trust and Authority: Our Commitment ()

As a leading provider of `mining chemicals`, our commitment to Google's standards — Expertise, Experience, Authoritativeness, and Trustworthiness — is foundational to our operations and client relationships.

Expertise and Authoritativeness:

- Certifications: Our manufacturing processes for sodium isopropyl xanthate adhere strictly to ISO 9001:2015 quality management systems, ensuring consistent product quality and process reliability. All products undergo rigorous testing according to national (e.g., GB/T) and international standards.

- Industry Leadership: With over two decades of dedicated service in the `mining chemicals` sector, we have cultivated deep expertise in flotation reagents, serving a global clientele. Our R&D team continuously innovates to meet evolving industry demands.

- Authoritative References: Our product data sheets and `sodium isopropyl xanthate msds` are meticulously prepared, citing relevant international safety and chemical standards, providing verifiable information for safe and effective use.

Trustworthiness and Customer Support:

- Lead Time and Fulfillment: We maintain strategically located production and warehousing facilities to ensure efficient global distribution. Standard lead times for sodium isopropyl xanthate orders typically range from 2-4 weeks, depending on volume and destination. Expedited options are available for urgent requirements.

- Warranty Commitments: All our products, including sodium isopropyl xanthate, are guaranteed to meet the published technical specifications. We offer a standard 12-month warranty from the date of shipment against manufacturing defects and non-conformance to specifications, provided proper storage and handling guidelines are followed.

- Customer Support: Our dedicated customer support team and technical service engineers are available 24/7 to address inquiries, provide technical assistance, and resolve any issues promptly. We offer multilingual support and on-site assistance as needed.

Frequently Asked Questions (FAQ):

- Q1: What is the recommended storage condition for sodium isopropyl xanthate?

- A1: Sodium isopropyl xanthate should be stored in a cool, dry, well-ventilated area, away from heat sources and direct sunlight. It should be kept in original, tightly sealed container111s to prevent moisture absorption and degradation. Avoid contact with strong acids and oxidizing agents.

- Q2: What are the primary safety considerations when handling SIPX?

- A2: SIPX is classified as hazardous. Personal protective equipment (PPE) including gloves, eye protection, and respiratory masks should always be worn. Avoid skin and eye contact, and inhalation of dust. Always refer to the `sodium isopropyl xanthate msds` for detailed safety instructions and emergency procedures.

- Q3: Can sodium isopropyl xanthate be used for non-sulfide mineral flotation?

- A3: While primarily effective for sulfide minerals, sodium isopropyl xanthate can, in some cases, be employed for the flotation of oxidized lead and copper minerals after sulfidization. Its application in other non-sulfide flotation circuits is less common but can be explored through specific metallurgical testing.

- Q4: What is the typical shelf life of sodium isopropyl xanthate?

- A4: When stored correctly in sealed packaging, the typical shelf life of sodium isopropyl xanthate is 12-24 months. Degradation can occur more rapidly under humid or high-temperature conditions.

Conclusion

Sodium isopropyl xanthate stands as a critical and highly effective collector in the realm of mineral processing. Its robust technical specifications, proven performance in diverse application scenarios, and inherent advantages in selectivity and recovery rates make it an indispensable `mining chemical` for achieving optimized metallurgical outcomes. As the industry continues to evolve towards more sustainable and efficient practices, the role of high-quality, reliable reagents like SIPX will only grow in importance. Partnering with experienced `sodium isopropyl xanthate suppliers` who prioritize quality, technical support, and customized solutions is paramount for operational success and long-term profitability in the challenging global mining landscape.

References

- Mineral Processing and Extractive Metallurgy Review, Taylor & Francis Online.

- International Journal of Mineral Processing, Elsevier.

- Schenck, G.H.K., et al. (2018). "Froth Flotation: A Century of Innovation." Society for Mining, Metallurgy & Exploration.

- Globally Sourced Market Research Reports on Mineral Processing Chemicals.

-

Best Chemicals Used to Disinfect Water – Comprehensive Guide & SolutionsNewsNov.19,2025

-

Comprehensive Guide to Chemical Disinfection of Water | Safe & Sustainable SolutionsNewsNov.18,2025

-

Bleach for Sanitizing Water – A Comprehensive Guide to Safe Water Treatment SolutionsNewsNov.18,2025

-

What Is Disinfectant Water? Uses, Benefits & Future Trends ExplainedNewsNov.18,2025

-

Comprehensive Guide to Chemicals That Disinfect Water for Global Safety and IndustryNewsNov.17,2025

-

Essential Chemicals Used for Disinfection of Water: Applications, Benefits & InnovationsNewsNov.15,2025

-

Comprehensive Guide on Chemicals to Disinfect Water: Uses, Benefits & TrendsNewsNov.15,2025