Sodium Isopropyl Xanthate | High-Purity Flotation Collector

A Field Note on Sodium Isopropyl Xanthate in Modern Flotation

If you’ve worked a rougher bank at 2 a.m., you already know the quiet power of a reliable collector. Lately, miners I speak with keep circling back to Sodium Isopropyl Xanthate (SIPX) because it’s predictable, easy to tune, and—when packaged right—clean to handle. FIZA’s pitch is straightforward: “Best price, premium quality.” Honestly, that’s the right order. Price opens the door; consistency keeps the contract.

What the industry is actually doing

Two trends are clear: dust-minimized pellets and steady supply from China-based producers with export-grade packaging. ESG pressure is also nudging plants toward tighter reagent housekeeping, better SDS transparency, and measurable QA data. In that context, Sodium Isopropyl Xanthate keeps winning because it’s versatile on Cu/Pb/Zn sulfides and behaves nicely across pH 7–11 (real-world plant water can be messy; SIPX is forgiving).

Product snapshot

| Parameter | Typical value (≈) | Method / Note |

|---|---|---|

| Active xanthate content | 85–90% | Iodometric titration (industry practice) |

| Free alkali (as NaOH) | ≤ 0.5–1.0% | Acid–base titration |

| Moisture & volatile | ≤ 4.0% | Karl Fischer, ISO 760 |

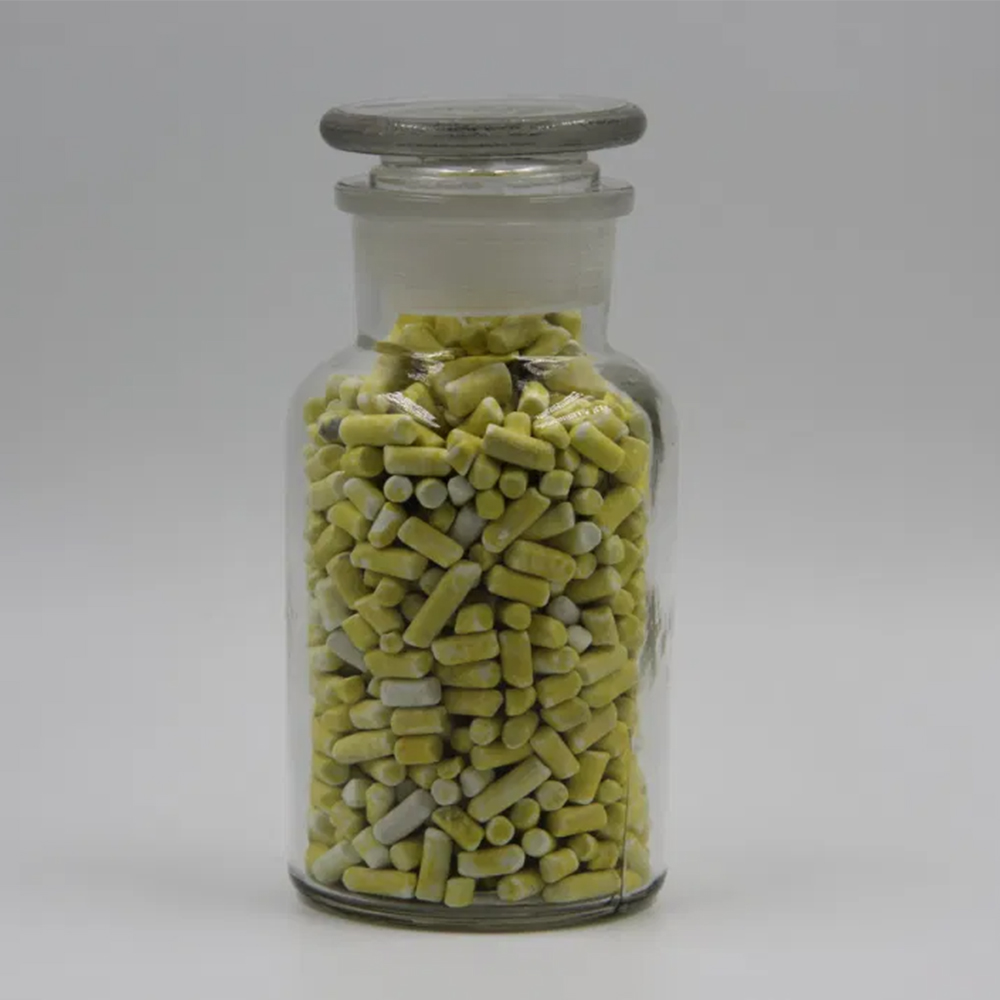

| Appearance | Yellowish pellets or powder | Low-dust packaging preferred |

| Solubility | Water-soluble | Prepare fresh solutions |

Process flow (how it’s made and checked)

- Materials: isopropanol + sodium hydroxide + carbon disulfide (handled in closed systems).

- Method: alkaline alcoholate route; controlled addition of CS2; temperature-managed reaction; stabilization.

- Finishing: filtration → pelletizing/granulation → drying → anti-caking → bagging (PE-lined).

- Testing: active content (iodometric), free alkali (titration), moisture (KF, ISO 760), solution pH, sieve analysis.

- Service life: ≈ 12 months sealed, cool/dry; shorten if repeatedly opened or exposed to heat/humidity.

- Certs: typical plants run ISO 9001 QMS; SDS aligned to GHS; many offer REACH support for EU shipments.

Applications and dosing

Primary use: sulfide ore flotation (copper, lead, zinc; sometimes nickel). Typical plant dosages sit around 10–80 g/t ore. To be honest, operators nudge it based on mineralogy, grind, and water chemistry. Works well with MIBC or polyglycol frothers; can be paired with dithiophosphates for selectivity tweaks. Keep pH 7–11 for stability and manageable froth.

Vendor snapshot (fast compare)

| Vendor | Purity spec | Packaging | Lead time | Certifications | Notes |

|---|---|---|---|---|---|

| FIZA (Shijiazhuang, CN) | ≥ 85% | 25 kg PE-lined bags; 850–900 kg FIBC | 2–4 weeks (typical) | ISO 9001, GHS SDS | Value-driven; steady Asia–LATAM lanes |

| Global Trader A | 85–90% | Bags/Jumbo | 4–6 weeks | REACH support | Broader blend options |

| Local Supplier B | ≈ 85% | Bags | 1–2 weeks regionally | QMS varies | Fast service; check QA data |

Customization

Plants often request: pellet size control (to cut dust), anti-caking tweaks, collector blends (e.g., Sodium Isopropyl Xanthate + dithiophosphate) for selectivity, and packaging with humidity indicators. It seems small, but these tweaks save shifts.

Case data (condensed)

A mid-size copper concentrator in the Andes swapped legacy collector for Sodium Isopropyl Xanthate pellets. After a two-week A/B run: +3.2% Cu recovery in roughers, −6% reagent cost per tonne, froth became slightly drier (operators loved that). Real-world use may vary, but the direction was clear.

Safety and handling

Keep away from acids (decomposition can release carbon disulfide vapors). Store cool, dry, ventilated; close bags tightly after use. Follow GHS/OSHA HazCom for labeling and PPE. Many customers say a simple “mix fresh daily” rule for solution prep prevents headaches.

References: [1] ISO 9001:2015 Quality management systems. [2] ISO 760:2018 Determination of water (Karl Fischer). [3] UN GHS Rev.9, Globally Harmonized System of Classification and Labelling of Chemicals. [4] OSHA 29 CFR 1910.1200 Hazard Communication. [5] SME Mining Engineering Handbook, Flotation Reagents section. [6] ECHA REACH Guidance for industrial chemicals.

-

How and Why to Disinfect Water Softeners for Safe, Reliable WaterNewsNov.24,2025

-

Effective Deionized Water Disinfectant Solutions for Healthcare & Industrial UseNewsNov.24,2025

-

Commonly Used Disinfectant for Drinking Water – Global Uses & InnovationsNewsNov.23,2025

-

Chemical to Disinfect Water – Essential Solutions for Safe, Clean Drinking WaterNewsNov.23,2025

-

Blue Water Disinfectant: Safeguarding Global Water Quality with InnovationNewsNov.22,2025

-

Bleaching Powder for Water Disinfection – Affordable & Effective Water Treatment SolutionNewsNov.22,2025

-

Bleaching Powder Drinking Water: Effective, Affordable Disinfection WorldwideNewsNov.21,2025