Effective Water Treatment Solutions for Cooling Tower Systems and Enhanced Performance

Cooling Tower Water Treatment Ensuring Efficiency and Longevity

Cooling towers play a crucial role in numerous industrial and commercial applications by dissipating excess heat from processes and machinery. The efficiency and longevity of a cooling tower heavily depend on effective water treatment practices. This article will explore the significance, methods, and benefits of cooling tower water treatment.

Importance of Water Treatment

Cooling towers use water to absorb heat from machinery or processes, which is then evaporated to release heat into the atmosphere. However, this makes the water susceptible to various contaminants, including biological organisms, mineral scale, and corrosion products. If left untreated, these contaminants can lead to

1. Scaling Minerals such as calcium and magnesium can precipitate out of the water, forming scale deposits on heat exchange surfaces. This scale acts as an insulating layer that reduces heat transfer efficiency, forcing the system to work harder and potentially leading to increased energy costs.

2. Corrosion Cooling tower water often contains dissolved oxygen and other corrosive agents. Corrosion can lead to significant damage and can compromise the structural integrity of pipes and heat exchangers, ultimately causing costly repairs and downtime.

3. Biological Growth The warm, moist environment of cooling towers fosters the growth of algae, bacteria, and other microorganisms. These biological contaminants can contribute to biofilm development, which further exacerbates scaling and corrosion issues, and can pose serious health risks, such as the spread of Legionnaires' disease.

Methods of Water Treatment

To address these potential threats, a comprehensive water treatment program should be implemented. Here are some common methods

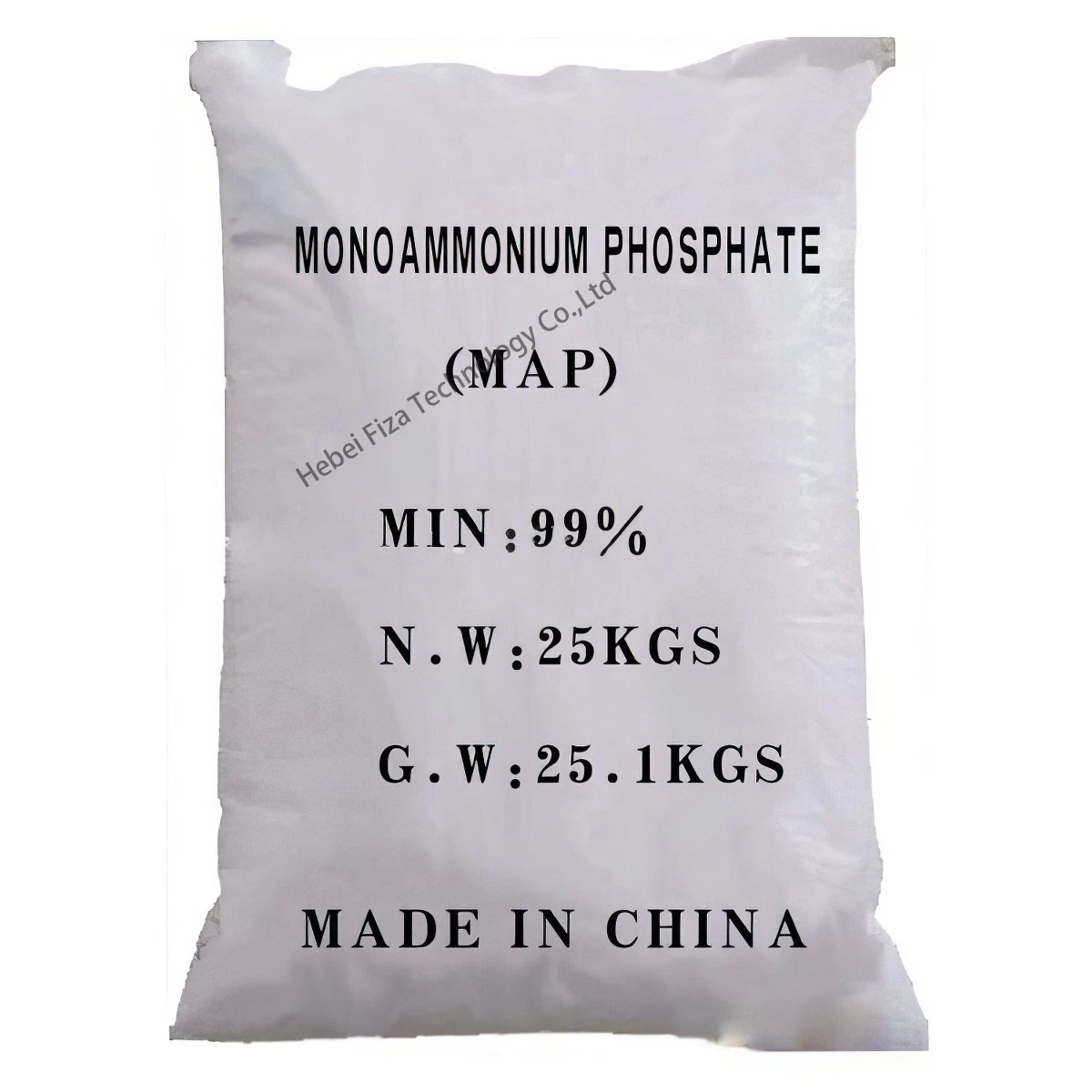

1. Chemical Treatments Various chemicals are used to treat cooling tower water, including

- Biocides These chemicals are designed to control biological growth

. Regular dosing with biocides helps keep algae and bacteria levels in check.- Corrosion Inhibitors These additives help to form a protective layer on metal surfaces to prevent oxidation and corrosion.

cooling tower water treatment pdf

- Scale Inhibitors These chemicals modify the crystal growth of minerals to prevent scaling within the cooling system.

2. Filtration Filtration systems remove particulate matter from the water, including sand, silt, and biological debris. Proper filtration helps maintain system cleanliness and efficiency.

3. Water Softening Using ion exchange processes, hard water can be softened to reduce mineral deposits that lead to scaling. This not only protects the cooling system but also enhances its operational efficiency.

4. Continuous Monitoring Regular monitoring is essential for effective water treatment. Automated systems can help track parameters such as pH, temperature, conductivity, and biocide levels, allowing for timely adjustments and ensuring optimal performance.

Benefits of Effective Water Treatment

Implementing a proper cooling tower water treatment program offers several benefits

1. Increased Efficiency By minimizing scaling and corrosion, cooling towers can operate more efficiently, improving energy consumption and reducing overhead costs.

2. Extended Equipment Lifespan Protecting the cooling system from damage prolongs its operational life, reducing the need for premature replacements and repairs.

3. Improved Safety A well-maintained cooling tower minimizes the risk of biological contamination, safeguarding employees and the surrounding community from potential health hazards.

4. Regulatory Compliance Many industries are subject to environmental regulations that necessitate specific water quality standards. Proper water treatment helps facilities comply with these regulations, avoiding fines and promoting responsible water usage.

Conclusion

In conclusion, effective water treatment is vital for the proper functioning of cooling towers. By using a combination of chemical treatments, filtration, and continuous monitoring, facilities can achieve optimal efficiency and longevity of their cooling systems. Investing in water treatment not only pays off through reduced operational costs but also enhances safety and compliance in industrial operations.

-

How and Why to Disinfect Water Softeners for Safe, Reliable WaterNewsNov.24,2025

-

Effective Deionized Water Disinfectant Solutions for Healthcare & Industrial UseNewsNov.24,2025

-

Commonly Used Disinfectant for Drinking Water – Global Uses & InnovationsNewsNov.23,2025

-

Chemical to Disinfect Water – Essential Solutions for Safe, Clean Drinking WaterNewsNov.23,2025

-

Blue Water Disinfectant: Safeguarding Global Water Quality with InnovationNewsNov.22,2025

-

Bleaching Powder for Water Disinfection – Affordable & Effective Water Treatment SolutionNewsNov.22,2025

-

Bleaching Powder Drinking Water: Effective, Affordable Disinfection WorldwideNewsNov.21,2025