Agro Chem Industries: Premium Agrochemicals & Fertilizers

Introduction to the Agro Chemical Industries Sector

The agro chem industries play a pivotal role in global agriculture, supporting food security and enhancing crop yields through the provision of essential chemical compounds. This sector encompasses a vast array of products, including fertilizers, pesticides (herbicides, insecticides, fungicides), plant growth regulators, and other soil amendments. The complexity of modern farming demands highly specialized and efficient solutions, driving continuous innovation within the industry. Companies operating within this space, such as Fizachem, are dedicated to delivering high-quality, reliable chemical inputs that meet stringent international standards and address the evolving needs of agricultural producers worldwide. Our focus is on providing materials that not only boost productivity but also align with sustainable practices and environmental stewardship.

Understanding the nuances of various agrochemicals types, their manufacturing processes, and their precise applications is critical for optimizing agricultural outcomes. This article delves into the technical aspects, market dynamics, and operational considerations pertinent to the sector, offering valuable insights for B2B decision-makers and technical professionals.

Current Trends in Agro Chem Industries

The global agro chem industries are undergoing significant transformation, driven by several key trends. Sustainability and environmental responsibility are at the forefront, pushing for the development of biodegradable, low-toxicity, and residue-free products. This includes a shift towards biological solutions and integrated pest management (IPM) strategies. Digital agriculture, leveraging IoT, AI, and big data, is also revolutionizing how agrochemicals are applied, enabling precision farming that optimizes dosage and timing, thereby reducing waste and environmental impact. Regulatory frameworks worldwide are becoming more stringent, demanding higher standards for product safety, efficacy, and environmental impact assessment. This necessitates robust R&D and rigorous testing protocols for all types of agrochemicals.

Emerging markets are experiencing rapid growth in demand for high-quality agro chemical fertilizers and crop protection products, fueled by population growth and increasing pressure on arable land. Innovation in nutrient delivery systems, such as slow-release and controlled-release fertilizers, is aimed at improving nutrient use efficiency and minimizing runoff. Furthermore, the consolidation of key players and the rise of specialized niche producers signify a dynamic competitive landscape, where technological advancement and customer-centric solutions are paramount.

Manufacturing Process: Sodium Nitrite for Agro-Chemical Applications

Sodium Nitrite (NaNO₂) is a critical inorganic compound with diverse applications, including significant use within the agro chem industries as a raw material for various formulations. The manufacturing process typically involves the absorption of nitric oxides (NOx) into an alkaline solution, most commonly sodium hydroxide (NaOH) or sodium carbonate (Na₂CO₃).

Process Flow Overview:

- Raw Material Sourcing: High-purity nitric acid (HNO₃) and sodium hydroxide (NaOH) are procured. Water with controlled parameters is also essential.

- Nitric Oxide Production: Nitric acid is typically reacted with a reducing agent (e.g., ammonia or sulfur dioxide) to produce nitric oxides (NOx), predominantly NO and NO₂.

-

Absorption and Reaction: The gaseous NOx mixture is then passed through an absorption tower where it reacts with a concentrated solution of sodium hydroxide. The primary reactions are:

- `NO + NO₂ + 2NaOH → 2NaNO₂ + H₂O`

- `2NO₂ + 2NaOH → NaNO₂ + NaNO₃ + H₂O` (Disproportionation, minimized by controlling NO/NO₂ ratio)

- Crystallization: The resulting solution, rich in Sodium Nitrite, is concentrated through evaporation. As the solution cools and water evaporates, Sodium Nitrite crystallizes out.

- Separation and Drying: The crystals are then separated from the mother liquor using centrifuges or filters. The wet crystals are subsequently dried in rotary dryers or fluid bed dryers to achieve the desired moisture content.

- Quality Control and Packaging: The dried Sodium Nitrite is subjected to rigorous quality control checks against established standards. Once approved, it is packaged into suitable container111s (e.g., 25kg bags, bulk bags) for distribution.

Testing Standards and Quality Assurance:

Fizachem's Sodium Nitrite production adheres strictly to international quality and safety standards. Key testing standards include:

- ISO 9001:2015: For Quality Management Systems, ensuring consistent product quality.

- ASTM E173: Standard Test Methods for Analysis of Sodium Nitrite.

- REACH Compliance: European Union regulation concerning the Registration, Evaluation, Authorization and Restriction of Chemicals.

- Food Chemical Codex (FCC) / USP Grade: For specific applications requiring high purity levels, though primary focus here is industrial and agro-chemical grade.

Service Life and Target Industries:

Sodium Nitrite, when stored properly in cool, dry conditions away from oxidizers and acids, has a typical shelf life of 1-2 years. Its stability makes it suitable for long-term storage and use in various industrial applications. Beyond its role in agro chemical fertilizers, Sodium Nitrite is crucial in sectors such as:

- Petrochemical Industry: Used as a corrosion inhibitor in cooling systems and oil pipelines.

- Metallurgy: Employed in metal treatment processes, particularly for phosphatizing and as an additive in pickling baths.

- Water Supply & Drainage: Functions as an oxygen scavenger and biocide in closed water systems to prevent microbial growth and corrosion.

- Construction: Used as an antifreeze admixture and corrosion inhibitor in concrete to protect rebar.

Our products are designed to offer significant advantages, including enhanced corrosion resistance in industrial systems and optimized performance in chemical synthesis, thereby contributing to energy saving and extending equipment longevity.

Technical Specifications and Parameters

Understanding the precise technical specifications of agrochemicals is paramount for ensuring optimal performance and safety. Our Sodium Nitrite product is manufactured to exacting standards, ensuring high purity and consistent quality for all industrial and agricultural applications. The table below outlines key parameters:

Sodium Nitrite (NaNO₂) Product Specifications (Industrial Grade):

| Parameter | Unit | Specification | Test Method |

|---|---|---|---|

| Sodium Nitrite (NaNO₂) | % | ≥ 99.0 | Titration (ASTM E173) |

| Sodium Nitrate (NaNO₃) | % | ≤ 0.5 | Ion Chromatography |

| Moisture | % | ≤ 0.1 | Gravimetric Method |

| Chlorides (as NaCl) | % | ≤ 0.05 | Argentometric Titration |

| Insolubles in Water | % | ≤ 0.02 | Gravimetric Method |

| Appearance | - | White to slightly yellowish crystalline powder | Visual Inspection |

| pH (1% solution) | - | 7.0 - 9.0 | pH Meter |

These specifications ensure that our Sodium Nitrite meets the stringent requirements for effective integration into various agrochemical formulations and industrial processes, guaranteeing performance and minimizing impurities that could compromise end-product quality.

Application Scenarios for Different Types of Agrochemicals

The diversity of different types of agrochemicals allows for tailored solutions across various agricultural and industrial contexts. Sodium Nitrite, while not a direct agrochemical fertilizer, serves as a crucial intermediate or additive in several formulations within the broader agro chem industries.

Key Application Areas:

- Corrosion Inhibition in Agricultural Equipment: Sodium Nitrite is a well-known anodic corrosion inhibitor. In liquid agro chemical fertilizers, particularly those with acidic pH or high salt content, it can be incorporated to protect the metallic components of storage tanks, spraying equipment, and irrigation systems from degradation, thereby extending their service life and reducing maintenance costs.

- Ingredient in Specialized Pesticide Formulations: Although less common, Sodium Nitrite can act as an excipient or inert ingredient in some specialized pesticide formulations, contributing to stability or specific reaction pathways. For example, it can be involved in the synthesis of certain organic compounds used as active ingredients.

- Water Treatment in Agricultural Settings: In large-scale agricultural operations that rely on pond or recycled water for irrigation, Sodium Nitrite can be used as an oxygen scavenger to prevent anaerobic conditions and reduce the corrosive potential of the water, protecting pumps and pipelines. This contributes to better water quality management critical for crop health.

- Soil Amendments for Nitrification Control: While primarily a nitrogen source in some contexts, its role in nitrification inhibition (slowing the conversion of ammonium to nitrate) is being explored to improve nitrogen use efficiency in certain soil types, ensuring nitrogen is available to plants for longer periods.

These diverse applications underscore the versatility of high-quality chemical inputs in optimizing agricultural processes and infrastructure, directly impacting operational efficiency and yield sustainability.

Technical Advantages and Benefits

Fizachem’s commitment to producing premium-grade Sodium Nitrite translates into significant technical advantages for our B2B partners in the agro chem industries and beyond. Our rigorous manufacturing and quality control processes ensure a product that delivers superior performance and reliability.

Key Advantages:

- High Purity & Consistency: Our Sodium Nitrite boasts a purity level of ≥ 99.0%, with minimal impurities like nitrates and chlorides. This high purity is critical for preventing unwanted side reactions in complex chemical formulations and ensures consistent performance, reducing batch variability for manufacturers of agrochemicals types.

- Superior Corrosion Inhibition: As a potent anodic inhibitor, our Sodium Nitrite effectively forms a passive layer on metal surfaces, significantly reducing corrosion rates in steel and iron. This is invaluable in protecting infrastructure in petrochemical, water treatment, and agricultural equipment contexts, leading to substantial savings on maintenance and replacement costs.

- Optimized Reactivity: The controlled particle size distribution and low moisture content of our Sodium Nitrite ensure predictable reactivity in chemical synthesis processes. This precision is vital for the efficient and cost-effective production of downstream chemical products or specific agro chemical fertilizers.

- Enhanced Product Stability: Our stringent packaging protocols and product stability testing ensure that Sodium Nitrite maintains its chemical integrity and efficacy over its stated shelf life, even under typical industrial storage conditions. This reduces product degradation and wastage.

- Environmental Responsibility: While Sodium Nitrite requires careful handling, our manufacturing process is optimized to minimize environmental footprint, including efficient wastewater treatment and emission control, aligning with industry best practices for sustainable chemical production.

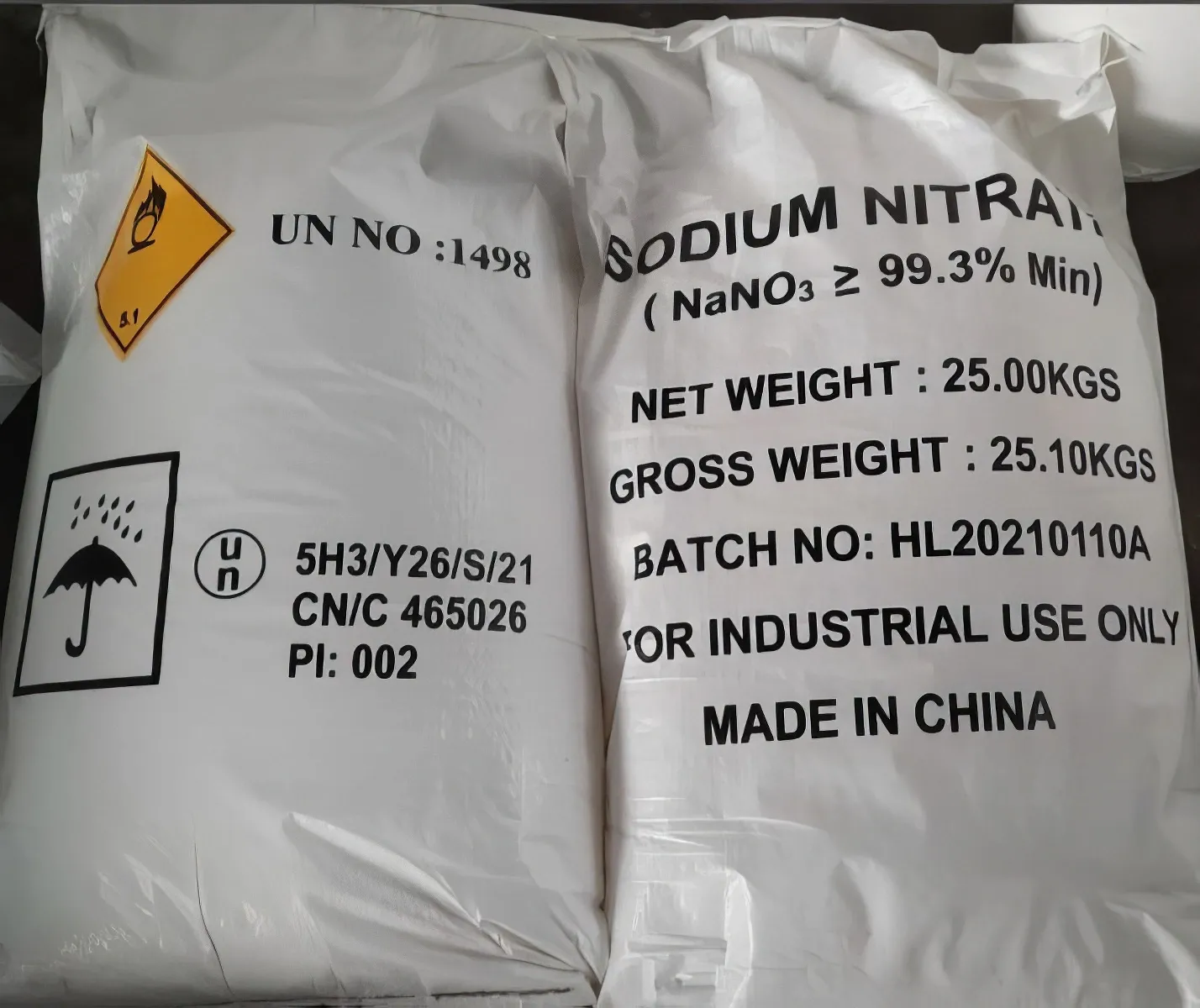

Figure 1: High-purity Sodium Nitrite granules, a key component in various agrochemical and industrial applications.

These advantages directly translate into improved operational efficiency, reduced overall costs, and higher quality end-products for our clients, solidifying our position as a trusted supplier in the chemical market.

Vendor Comparison: Choosing the Right Partner in Agro Chem Industries

Selecting a reliable supplier for critical chemical inputs in the agro chem industries is a strategic decision that impacts product quality, supply chain stability, and cost-efficiency. While many vendors offer various agrochemicals types, Fizachem distinguishes itself through a multi-faceted approach centered on quality, service, and technical expertise.

Key Differentiators for Fizachem:

| Feature | Fizachem | Typical Competitor |

|---|---|---|

| Product Purity (Sodium Nitrite) | ≥ 99.0% (Guaranteed) | Often 98.5% - 99.0% |

| Certifications & Compliance | ISO 9001:2015, REACH Registered, stringent internal QA | May vary; basic certifications only |

| Technical Support & Expertise | Dedicated R&D team, application specialists, rapid response | Limited or outsourced support |

| Supply Chain Reliability | Diversified sourcing, optimized logistics, buffer stock | Single-source dependency, potential for delays |

| Customization & Flexibility | Tailored specifications, packaging, and delivery schedules | Standard product offerings only |

| Experience & Track Record | Years of proven service to global B2B clients, strong client testimonials | Newer entrant or less diversified client base |

Our commitment to consistent quality, robust supply chain management, and unparalleled technical support positions Fizachem as a preferred partner for companies seeking reliable and high-performance chemical solutions. We understand the critical nature of agricultural inputs and strive to exceed expectations.

Customized Solutions for Diverse Agro-Chemical Needs

Recognizing that standard products may not always perfectly align with highly specialized application requirements, Fizachem offers extensive customization capabilities for our Sodium Nitrite products and other chemical offerings relevant to the agro chem industries. Our technical team works closely with clients to develop bespoke solutions that precisely meet their unique specifications.

Areas of Customization:

- Purity Adjustments: While our standard industrial grade is ≥99.0%, we can adjust purity levels for specific applications that demand even higher thresholds, or for cost-optimization where slightly lower purity is acceptable without compromising performance for certain types of agrochemicals.

- Particle Size Distribution: For applications requiring precise dissolution rates or dispersion characteristics, we can provide Sodium Nitrite with a custom particle size range, from fine powders to coarser granules. This is particularly relevant for certain agro chemical fertilizers or soil amendments.

- Packaging & Logistics: Beyond standard 25kg bags or bulk bags, we can accommodate specific packaging requirements, including specialized drum sizes, moisture-proof liners, or even custom labeling for seamless integration into your supply chain. We also work with clients on optimized delivery schedules.

- Formulation Compatibility Testing: Our R&D team can assist with compatibility testing of our Sodium Nitrite with other components in your specific agrochemical or industrial formulations, ensuring stability and preventing undesired reactions.

This flexible approach ensures that our clients receive not just a chemical, but a precisely engineered solution that enhances their manufacturing efficiency and end-product quality, fostering long-term partnerships built on trust and performance.

Application Case Studies

Case Study 1: Enhanced Corrosion Protection in Fertilizer Production Facilities

A major producer of liquid nitrogen-based agro chemical fertilizers faced significant challenges with corrosion in their steel storage tanks and piping systems. The acidic nature and high ionic strength of their formulations led to rapid material degradation, increasing maintenance costs and risking operational downtime. Fizachem collaborated with their engineering team to integrate high-purity Sodium Nitrite into their closed-loop cooling systems and as a passivation agent for new tank installations. Over an 18-month period, the client reported a 45% reduction in documented corrosion incidents and a 30% extension in the projected service life of their critical infrastructure. This translated into an estimated annual saving of $150,000 in repair and replacement costs, directly attributable to the superior corrosion inhibition provided by our Sodium Nitrite.

Case Study 2: Optimization of Water Treatment for Large-Scale Irrigation

A large agricultural cooperative managing vast irrigation networks experienced frequent blockages and accelerated wear in their pumping stations and distribution lines due to microbial growth and iron deposition from raw water sources. After a comprehensive water analysis, Fizachem recommended a tailored water treatment regimen that included controlled dosing of our Sodium Nitrite as an oxygen scavenger and biostatic agent. Within six months, the cooperative observed a 70% reduction in biofilm formation and a notable decrease in iron-related scaling. Pump efficiency improved by an average of 12%, and the frequency of system flushing and manual cleaning decreased by 60%. This solution not only prolonged the lifespan of their expensive irrigation infrastructure but also ensured a more consistent and higher quality water supply for their crops.

Case Study 3: Improved Stability in Specialty Agrochemical Formulations

A European manufacturer of specialty crop protection products required a stabilizing agent for a new herbicide formulation, where an intermediate compound was highly susceptible to oxidative degradation during storage. Traditional stabilizers proved inadequate, leading to inconsistent product efficacy and reduced shelf life. Fizachem provided a custom-grade Sodium Nitrite with ultra-low moisture and specific particle sizing. Through pilot trials, the client found that incorporating our tailored Sodium Nitrite at a precise concentration significantly enhanced the oxidative stability of their formulation, extending its effective shelf life by an additional 6 months. This allowed them to meet strict regulatory requirements for product stability and expanded their market reach for this innovative herbicide.

Frequently Asked Questions (FAQ)

Q1: What is the primary role of Sodium Nitrite in the agro chem industries?

A1: While not a direct fertilizer, Sodium Nitrite plays a crucial role as an intermediate in chemical synthesis, a corrosion inhibitor for agricultural equipment, and a water treatment agent to protect irrigation systems. It also has potential applications in controlling nitrification in soil.

Q2: How does Fizachem ensure the quality and purity of its Sodium Nitrite?

A2: Our Sodium Nitrite production adheres to strict ISO 9001:2015 quality management standards. We employ advanced manufacturing processes, meticulous raw material selection, and rigorous in-house testing following standards like ASTM E173 to ensure a minimum 99.0% purity and consistency.

Q3: Can Sodium Nitrite be customized for specific agrochemical formulations?

A3: Yes, Fizachem specializes in providing customized solutions. We can tailor purity levels, particle size distribution, and packaging options to meet the precise requirements of your unique agrochemical formulations or industrial processes.

Q4: What are the lead times for Sodium Nitrite orders?

A4: Standard lead times for common quantities are typically 2-4 weeks, depending on inventory levels and destination. For large volume or customized orders, lead times will be communicated upon inquiry, with our logistics team working to ensure efficient and timely delivery.

Lead Time, Warranty, and After-Sales Support

Lead Time & Fulfillment:

Fizachem maintains robust supply chain management to ensure consistent and timely delivery. For standard Sodium Nitrite products, typical lead times for North American and European markets range from 14 to 28 days from order confirmation, depending on volume and specific logistical requirements. For urgent requests or specialized shipments, expedited options can be arranged. We leverage a global network of logistics partners to optimize transit times and ensure product integrity upon arrival. Clients receive regular updates on order status and estimated delivery.

Warranty Commitments:

Fizachem warrants that its Sodium Nitrite products conform to the published specifications and are free from defects in material and workmanship at the time of shipment. Our products are accompanied by a Certificate of Analysis (CoA) for each batch. We provide a warranty period of 12 months from the date of shipment, provided the product is stored and handled according to our recommendations and industry best practices. Any claims for non-conformity must be submitted within this period, allowing for thorough investigation and resolution. Our commitment extends to ensuring product suitability for the intended industrial and agro-chemical applications as per our technical data sheets.

Customer Support & Technical Assistance:

Our dedication to client success extends far beyond product delivery. Fizachem offers comprehensive after-sales support, including expert technical assistance for product application, troubleshooting, and optimization within your processes. Our team of experienced chemists and application specialists is available for consultation via phone, email, and virtual meetings. We provide ongoing support for regulatory compliance inquiries and offer guidance on safe handling and storage. We believe in building enduring partnerships through proactive communication and responsive service, ensuring our clients derive maximum value from our chemical solutions in the dynamic agro chem industries landscape.

References

- U.S. Environmental Protection Agency. (2023). Agrochemicals: Understanding Their Role in Modern Agriculture.

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems — Requirements.

- American Society for Testing and Materials. (2022). ASTM E173 - Standard Test Methods for Analysis of Sodium Nitrite.

- European Chemicals Agency (ECHA). (2023). REACH Regulation Information on chemicals.

- Food and Agriculture Organization of the United Nations. (2023). The State of Food and Agriculture 2023.

-

How and Why to Disinfect Water Softeners for Safe, Reliable WaterNewsNov.24,2025

-

Effective Deionized Water Disinfectant Solutions for Healthcare & Industrial UseNewsNov.24,2025

-

Commonly Used Disinfectant for Drinking Water – Global Uses & InnovationsNewsNov.23,2025

-

Chemical to Disinfect Water – Essential Solutions for Safe, Clean Drinking WaterNewsNov.23,2025

-

Blue Water Disinfectant: Safeguarding Global Water Quality with InnovationNewsNov.22,2025

-

Bleaching Powder for Water Disinfection – Affordable & Effective Water Treatment SolutionNewsNov.22,2025

-

Bleaching Powder Drinking Water: Effective, Affordable Disinfection WorldwideNewsNov.21,2025