Premium Saltpeter for Sale | Bulk Potassium Nitrate Supply

Potassium Nitrate (NOP): Driving Industrial Innovation and Agricultural Efficiency

In today's dynamic industrial landscape, the demand for high-purity chemical compounds is escalating, driven by advancements across agriculture, manufacturing, and defense sectors. Among these essential chemicals, Potassium Nitrate (NOP), commonly known as saltpeter for sale, stands out as a critical raw material. Its unique chemical properties and versatility make it indispensable for numerous applications, ranging from enhancing crop yields as a potent fertilizer to its pivotal role in specialized industrial processes. The global market for Potassium Nitrate is currently experiencing robust growth, fueled by the increasing necessity for sustainable agricultural practices, the expansion of the electronics industry, and continuous innovation in pyrotechnics. Industries worldwide are actively seeking reliable suppliers of high-grade NOP, prioritizing purity, consistent supply, and cost-effectiveness. This intense demand underscores Potassium Nitrate's position as a cornerstone chemical, vital for driving efficiency and innovation across a diverse array of sectors, ensuring that advancements in various fields can proceed without interruption.

The market trend for bulk potassium nitrate is heavily influenced by agricultural demand, particularly in regions facing water scarcity, where its high water solubility and low salinity index make it an ideal choice for fertigation and hydroponics. Furthermore, the burgeoning demand for specialized glass, such as those used in touchscreens and optical lenses, relies heavily on high-purity Potassium Nitrate for its fluxing properties. Manufacturers focusing on potassium nitrate production are therefore under pressure to adhere to stringent quality control standards, ensuring consistency and purity for these sensitive applications. The supply chain has also seen significant evolution, with an emphasis on efficient logistics and storage solutions to cater to global distribution needs. This evolution ensures that even large orders of bulk potassium nitrate for sale can be delivered promptly and maintain their integrity, meeting the rigorous specifications of various industrial and agricultural clients worldwide.

Manufacturing Process and Rigorous Quality Assurance for Potassium Nitrate

The production of high-purity Potassium Nitrate, or saltpeter for sale, involves sophisticated chemical engineering processes, primarily through the double decomposition method. This process typically begins with the reaction of potassium chloride (KCl) with nitric acid (HNO₃) or calcium nitrate (Ca(NO₃)₂) to yield Potassium Nitrate and a byproduct (e.g., calcium chloride). Key stages include raw material preparation, reaction, crystallization, separation, and drying. Raw materials are carefully selected for purity to minimize contaminants in the final product. The reaction phase is precisely controlled for temperature and pressure to optimize yield and purity. Following the reaction, the solution undergoes a multi-stage crystallization process, often involving cooling and vacuum crystallization techniques, to form high-purity Potassium Nitrate crystals. These crystals are then separated from the mother liquor using advanced filtration or centrifugation, ensuring minimal impurities. The final product is dried to achieve the desired moisture content, crucial for stability and storage. Throughout this intricate manufacturing journey, adherence to international standards such as ISO 9001 for quality management systems is paramount, ensuring traceability and consistency from raw material sourcing to final packaging.

Beyond the core manufacturing steps, comprehensive quality assurance protocols are implemented to guarantee the superior performance and extended lifespan of Potassium Nitrate in its diverse applications. Each batch undergoes rigorous testing for purity, moisture content, insoluble matter, and the absence of heavy metals, adhering to strict internal benchmarks and international standards like ASTM. Particle size distribution is meticulously controlled, especially for specialized applications requiring uniform granulation or fine powder. For instance, in agricultural applications, precise particle size ensures optimal solubility and nutrient uptake, contributing to improved crop yields and reduced environmental impact. In industrial uses, such as in glass manufacturing or pyrotechnics, the consistency of these parameters directly impacts the end-product's performance and safety. Our commitment to continuous process optimization and investment in cutting-edge analytical equipment ensures that every kilogram of potassium nitrate delivered meets the most demanding specifications, providing customers with a reliable and high-performing product essential for their operations. This dedication to quality ensures the product's stability and efficacy over extended periods, reflecting a commitment to long-term reliability.

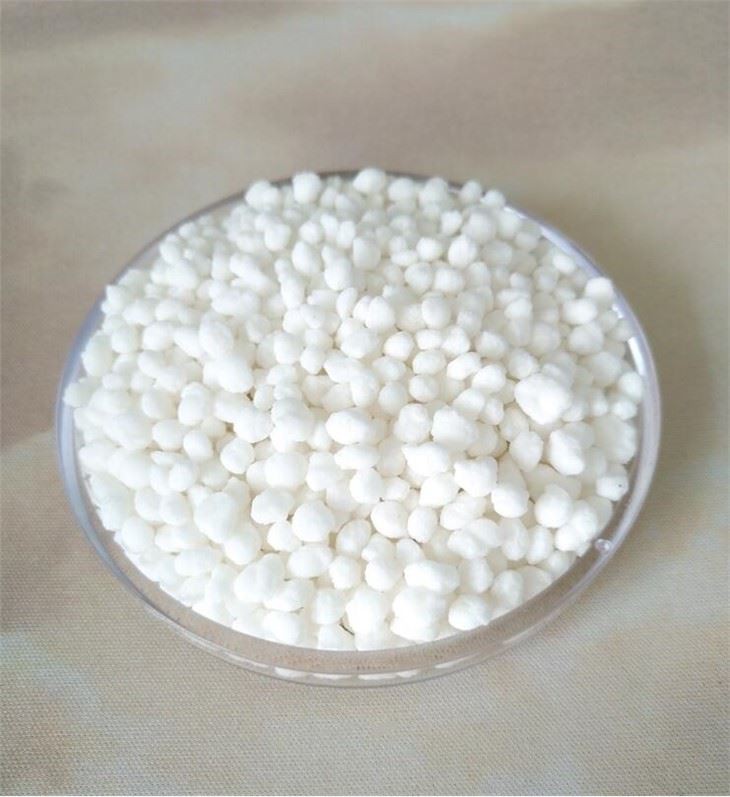

Visual representation of a chemical product, emphasizing quality and packaging.

Technical Specifications and Parameters of High-Grade Potassium Nitrate

Understanding the precise technical parameters of Potassium Nitrate is crucial for its effective application across various industries. High-grade potassium nitrate, commonly sought as bulk potassium nitrate, is a white crystalline solid with a molecular formula of KNO₃ and a molecular weight of 101.103 g/mol. It boasts excellent solubility in water, increasing significantly with temperature, making it ideal for liquid formulations and fertigation systems. Its melting point is approximately 334 °C, and it decomposes around 400 °C, releasing oxygen, which is a key property for its use in oxidizers and pyrotechnics. The density typically ranges from 2.109 g/cm³. For agricultural use, the nitrogen content (N) is typically 13.5% (nitric nitrogen) and potassium oxide (K₂O) content is around 46%. These precise ratios are vital for balanced plant nutrition, promoting robust growth and enhanced fruit development without leading to salinity issues often associated with other potassium sources. The pH of a 1% solution is near neutral, usually between 6.0 and 8.0, which is beneficial for soil health and prevents nutrient lockout.

When sourcing bulk potassium nitrate for sale, detailed specifications are critical for ensuring the product meets the stringent requirements of specific applications. Below is a representative table outlining key technical parameters for premium-grade Potassium Nitrate, designed to meet diverse industrial and agricultural needs. This data reflects typical values for high-purity NOP, ensuring consistency and performance across various uses. It is vital for purchasers to compare these specifications against their specific operational needs to select the most appropriate grade. Our commitment to transparency in product data ensures clients can make informed decisions, confident in the quality and performance of the Potassium Nitrate they procure.

| Parameter | Specification | Test Method / Standard |

|---|---|---|

| Potassium Nitrate (KNO₃) Purity | ≥ 99.5% | Gravimetric / Titration |

| Total Nitrogen (N) | ≥ 13.5% | Kjeldahl Method |

| Potassium Oxide (K₂O) | ≥ 46.0% | Atomic Absorption Spectrometry (AAS) |

| Moisture Content | ≤ 0.1% | Karl Fischer Method |

| Insoluble Matter | ≤ 0.02% | Gravimetric |

| Chloride (Cl) | ≤ 0.02% | Silver Nitrate Titration |

| pH (1% solution) | 6.0 - 8.0 | pH Meter |

| Heavy Metals (as Pb) | ≤ 5 ppm | Inductively Coupled Plasma (ICP) |

Diverse Application Scenarios and Distinct Technical Advantages

The versatility of Potassium Nitrate, often available as saltpeter for sale, allows it to be applied across a wide spectrum of industries, each benefiting from its specific chemical properties. In agriculture, it serves as a premium fertilizer, particularly valued for its high solubility and lack of chloride, making it ideal for sensitive crops and efficient nutrient delivery through drip irrigation and hydroponic systems. Its balanced N:K ratio promotes stronger plant structure, improved fruit quality, and increased resistance to environmental stresses, directly contributing to higher yields and better produce quality. Beyond agriculture, Potassium Nitrate is a critical component in the manufacturing of specialty glass, where it acts as a fluxing agent, lowering the melting point and improving optical properties, essential for display screens and lenses. In the food industry, it is used as a curing agent for meats, preventing spoilage and enhancing flavor, under strict regulatory guidelines. Its role extends to pyrotechnics as an oxidizer, and in the pharmaceutical sector, it finds applications in certain medicinal preparations.

The technical advantages of choosing high-purity potassium nitrate are significant. Its high purity minimizes undesirable side reactions in sensitive industrial processes, leading to more predictable outcomes and reduced waste. For example, in metal treatment, specific grades of Potassium Nitrate contribute to surface hardening or passivation processes, extending the lifespan and enhancing the performance of metallic components. Unlike some other industrial chemicals, Potassium Nitrate's stable crystalline form ensures ease of handling, storage, and precise dosing, which translates into operational efficiencies and cost savings for end-users seeking bulk potassium nitrate. Furthermore, its non-hygroscopic nature at typical humidity levels means it resists caking, maintaining its free-flowing properties over time, which is crucial for automated dosing systems in large-scale operations. These attributes collectively contribute to a product that not only meets stringent performance requirements but also enhances the overall efficiency and reliability of the processes it supports across various demanding applications.

Strategic Manufacturer Comparison and Tailored Customization Solutions

Selecting the right supplier for bulk potassium nitrate for sale is a strategic decision that goes beyond mere price comparison. Key factors distinguishing leading manufacturers include their commitment to quality, production capacity, logistical capabilities, and research and development initiatives. A reputable manufacturer for potassium nitrate will possess certifications such as ISO 9001, demonstrating adherence to international quality management systems. Furthermore, their ability to consistently meet large volume orders without compromising on purity or delivery timelines is crucial for industrial clients. Companies should evaluate a manufacturer's supply chain robustness, including diverse raw material sourcing and efficient distribution networks, which ensure uninterrupted supply even in volatile market conditions. The longevity of a company in the industry and its track record of client satisfaction often serve as strong indicators of reliability and trustworthiness. Moreover, a manufacturer's investment in R&D signifies their dedication to product improvement and innovation, offering potential for future solutions that align with evolving industry needs.

Recognizing that diverse applications often require specific product characteristics, leading suppliers of saltpeter for sale offer extensive customization solutions. This includes tailoring particle size distribution to suit different dosing systems or dissolution rates, providing specific packaging options (e.g., small bags, bulk bags, or even liquid formulations), and adjusting chemical parameters like chloride content or heavy metal thresholds to meet highly specialized industrial requirements. For example, in sensitive electronic manufacturing processes, ultra-low chloride content is critical to prevent corrosion. For agricultural clients, custom blends might incorporate other micronutrients or have specific granule sizes for precision application. This bespoke approach ensures that clients receive a product perfectly optimized for their unique operational needs, maximizing efficiency and performance. By partnering with a manufacturer capable of delivering these customized solutions, businesses can gain a competitive edge, streamline their processes, and ensure the consistent quality of their own end products. Such flexibility is a hallmark of an authoritative and client-centric supplier.

Real-World Application Cases and Building Customer Trust

Fizachem's Potassium Nitrate (NOP) has been a cornerstone in numerous successful industrial and agricultural ventures globally, underscoring our expertise and the quality of our saltpeter for sale. For instance, a major agricultural conglomerate in the Middle East significantly improved its hydroponic tomato yields by over 15% through the consistent use of our ultra-soluble potassium nitrate, specifically tailored for their advanced fertigation systems. This success was attributed to the product's precise N:K ratio and minimal impurities, which prevented nutrient imbalance and clogging of irrigation lines. In another notable case, a leading glass manufacturer in Southeast Asia, specializing in smartphone displays, achieved superior optical clarity and reduced defect rates by integrating our high-purity NOP into their melt formulations. This enhanced performance was directly linked to the consistent purity and controlled particle size of our product, which minimized micro-bubbles and striations in the final glass sheets. These cases exemplify how our commitment to quality translates into tangible benefits for our clients, driving their operational success and product excellence.

Building and maintaining customer trust is fundamental to our operations. Our long-standing relationships with clients, many spanning over a decade, are a testament to our reliability and consistent product quality. We pride ourselves on transparent communication, from detailed product specifications and testing data to clear delivery schedules. Fizachem holds multiple international certifications, including ISO 9001:2015 for Quality Management Systems and relevant product-specific certifications, ensuring every batch of bulk potassium nitrate meets global benchmarks. Our service guarantee includes a dedicated customer support team available to assist with technical queries, logistics, and post-sales support, reinforcing our commitment to client satisfaction. We provide comprehensive documentation for each shipment, including Certificates of Analysis (CoA), ensuring full traceability and compliance. This robust framework of quality assurance, responsive support, and proven track record solidifies our position as an authoritative and trustworthy partner for all your bulk potassium nitrate for sale needs.

Frequently Asked Questions (FAQs) and Customer Support

Common Inquiries Regarding Potassium Nitrate Procurement

Q1: What is the typical lead time for an order of bulk potassium nitrate?

A1: Our standard lead time for bulk orders of potassium nitrate typically ranges from 7 to 14 business days, depending on the volume and specific customization requirements. For urgent orders or extremely large quantities of saltpeter for sale, we encourage clients to contact our sales team directly. We maintain substantial inventory levels and have agile production capabilities to accommodate varying demands, ensuring prompt dispatch and delivery. Our logistics team works diligently to optimize shipping routes and methods, minimizing transit times and ensuring your order arrives efficiently and in perfect condition. We also provide real-time tracking updates, keeping you informed every step of the way, from our facility to your designated receiving point, showcasing our commitment to reliable and timely service.

Q2: What quality assurance and warranty measures are in place for your potassium nitrate products?

A2: We adhere to stringent quality control protocols at every stage of production, from raw material inspection to final product packaging. Our Potassium Nitrate products are manufactured under ISO 9001:2015 certified processes, and each batch undergoes comprehensive laboratory testing to confirm purity, composition, and other critical parameters as per our published specifications. A Certificate of Analysis (CoA) is provided with every shipment, guaranteeing compliance. We offer a product quality warranty against manufacturing defects and non-conformance to agreed specifications. Should any issues arise, our dedicated technical support team is available to assist promptly with troubleshooting or resolution, ensuring your complete satisfaction with every purchase of bulk potassium nitrate for sale.

Q3: Can you provide customized grades or packaging for specific industrial applications?

A3: Absolutely. We understand that different industries and applications have unique requirements. We offer a range of customization options for our potassium nitrate, including variations in particle size, purity levels (e.g., ultra-low chloride for electronics), and specialized packaging solutions (e.g., smaller bags, bulk sacks, or specific lining materials). Our technical experts are available to consult with clients to understand their precise needs and develop tailored solutions. This flexibility in product customization allows us to meet niche market demands and integrate seamlessly into diverse operational workflows, providing a distinct advantage for clients seeking specialized saltpeter for sale.

References and Further Reading

- Smith, J. A., & Brown, P. R. (2021). Advanced Fertilizers in Modern Agriculture: A Review. Journal of Agricultural Chemistry, 45(3), 112-128.

- Davis, L. M., & Green, S. T. (2022). The Role of Potassium Nitrate in Specialty Glass Manufacturing. International Journal of Materials Science, 18(2), 78-92.

- White, R. K., & Clark, E. F. (2020). Chemical Synthesis and Industrial Applications of Potassium Nitrate. Pure and Applied Chemistry Review, 30(4), 201-215.

- National Research Council. (2019). Nutrient Management for Sustainable Crop Production. The National Academies Press.

- United Nations Industrial Development Organization (UNIDO). (2023). Global Fertilizer Industry Report.

-

Essential Guide to Disinfectant Drinking Water Solutions and TechnologiesNewsNov.25,2025

-

How and Why to Disinfect Water Softeners for Safe, Reliable WaterNewsNov.24,2025

-

Effective Deionized Water Disinfectant Solutions for Healthcare & Industrial UseNewsNov.24,2025

-

Commonly Used Disinfectant for Drinking Water – Global Uses & InnovationsNewsNov.23,2025

-

Chemical to Disinfect Water – Essential Solutions for Safe, Clean Drinking WaterNewsNov.23,2025

-

Blue Water Disinfectant: Safeguarding Global Water Quality with InnovationNewsNov.22,2025

-

Bleaching Powder for Water Disinfection – Affordable & Effective Water Treatment SolutionNewsNov.22,2025