Sodium Chlorite Solution

Jan . 09, 2025 10:36

Back to list

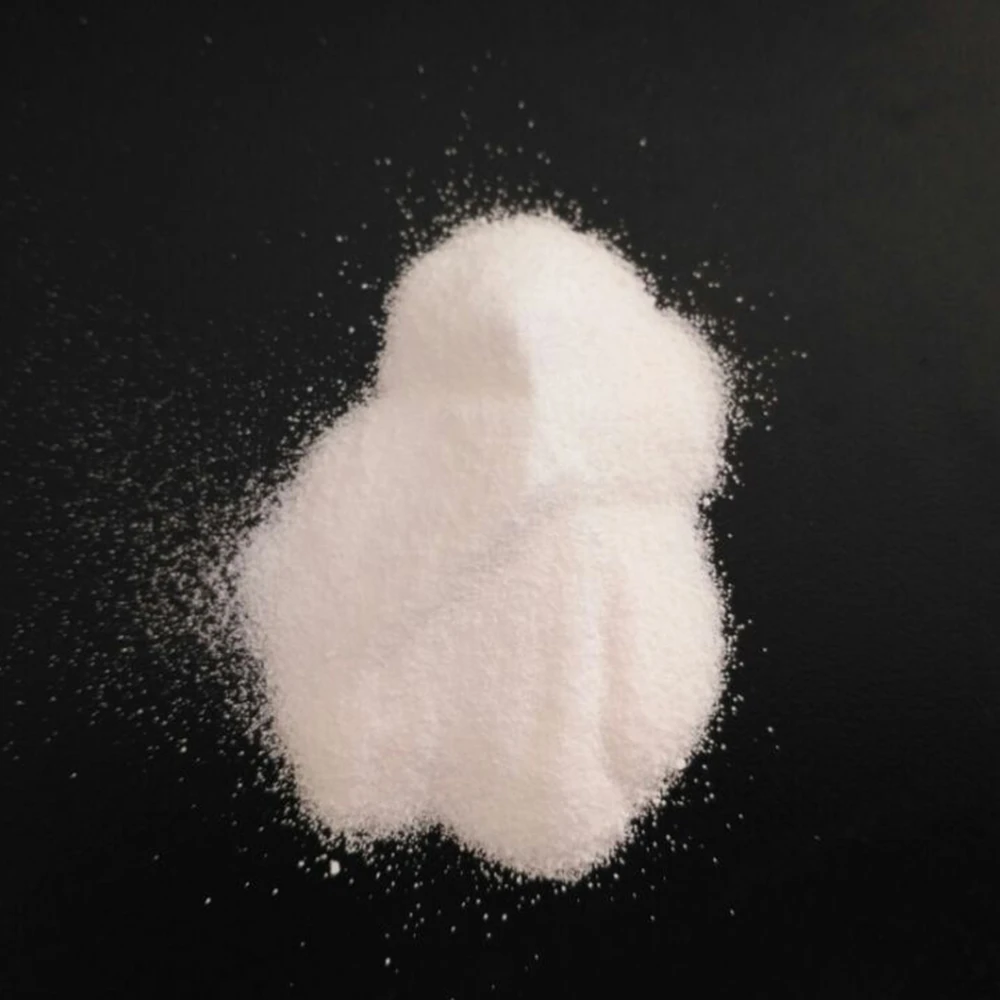

Sodium Chlorite Solution

Navigating the competitive landscape of sodium chlorite manufacturing requires a comprehensive understanding of industry trends, expertise in chemical production, a solid reputation for quality, and unwavering trustworthiness. As one delves into the niche yet critical market of sodium chlorite, these principles become increasingly significant for businesses aiming to dominate the sector.

Authoritativeness in this industry is garnered through a legacy of quality and compliance with global standards. A manufacturer’s reputation hinges on their ability to produce sodium chlorite that meets and exceeds international quality metrics, securing certifications from recognized bodies and exhibiting compliance with environmental and safety regulations. Such authoritative standing is often amplified by active participation in industry forums, symposiums, and collaborations with academic and research institutions, all of which underscore a commitment to innovation and leadership in the field. Trustworthiness, meanwhile, is the cornerstone of long-term relationships in sodium chlorite manufacturing. Transparency in operations, ethical sourcing of raw materials, and a robust supply chain strategy play integral roles in establishing trust. Manufacturers who maintain open lines of communication with partners and clients, offering not just products but also technical support and advice, are more likely to be perceived as reliable. In an industry where even minor deviations in chemical composition can have significant repercussions, the assurance of product integrity is invaluable. Through the lens of these four critical indicators, it is clear that succeeding as a sodium chlorite manufacturer requires more than just producing a chemical compound. It demands an unwavering commitment to quality, safety, and innovation. It necessitates an authoritative presence in the industry, built upon trust and robust relationships with collaborators and clients alike. With these principles at the core, a manufacturer not only prospers but also paves the way for advancements within the sphere of sodium chlorite applications, contributing significantly to global needs that range from safe drinking water to efficient textile processing.

Authoritativeness in this industry is garnered through a legacy of quality and compliance with global standards. A manufacturer’s reputation hinges on their ability to produce sodium chlorite that meets and exceeds international quality metrics, securing certifications from recognized bodies and exhibiting compliance with environmental and safety regulations. Such authoritative standing is often amplified by active participation in industry forums, symposiums, and collaborations with academic and research institutions, all of which underscore a commitment to innovation and leadership in the field. Trustworthiness, meanwhile, is the cornerstone of long-term relationships in sodium chlorite manufacturing. Transparency in operations, ethical sourcing of raw materials, and a robust supply chain strategy play integral roles in establishing trust. Manufacturers who maintain open lines of communication with partners and clients, offering not just products but also technical support and advice, are more likely to be perceived as reliable. In an industry where even minor deviations in chemical composition can have significant repercussions, the assurance of product integrity is invaluable. Through the lens of these four critical indicators, it is clear that succeeding as a sodium chlorite manufacturer requires more than just producing a chemical compound. It demands an unwavering commitment to quality, safety, and innovation. It necessitates an authoritative presence in the industry, built upon trust and robust relationships with collaborators and clients alike. With these principles at the core, a manufacturer not only prospers but also paves the way for advancements within the sphere of sodium chlorite applications, contributing significantly to global needs that range from safe drinking water to efficient textile processing.

Prev:

Next:

Latest news

-

Why Sodium Persulfate Is Everywhere NowNewsJul.07,2025

-

Why Polyacrylamide Is in High DemandNewsJul.07,2025

-

Understanding Paint Chemicals and Their ApplicationsNewsJul.07,2025

-

Smart Use Of Mining ChemicalsNewsJul.07,2025

-

Practical Uses of Potassium MonopersulfateNewsJul.07,2025

-

Agrochemicals In Real FarmingNewsJul.07,2025

-

Sodium Chlorite Hot UsesNewsJul.01,2025